Ukusebenza okuqhelekileyo kwe-injini kunokwenzeka kuphela ukuba i-crankshaft yayo ayinayo i-axial displacement ebalulekileyo - umva.Isikhundla esizinzile se-shaft sinikezelwa ngamacandelo akhethekileyo - i-half-thrust-rings.Funda malunga ne-crankshaft half-rings, iintlobo zazo, ukuyila, ukukhetha kunye nokutshintshwa kweli nqaku.

Yintoni i-half-ring yenkxaso ye-crankshaft?

Inzwa yoxinzelelo lweoyile yinto enovelwano yezixhobo kunye nezixhobo ze-alamu zenkqubo yokuthambisa yokubuyisela iinjini zokutsha zangaphakathi;Inzwa yokulinganisa uxinzelelo kwinkqubo yokuthambisa kunye nokubonakalisa ukuncipha kwayo ngaphantsi kwinqanaba elibalulekileyo.

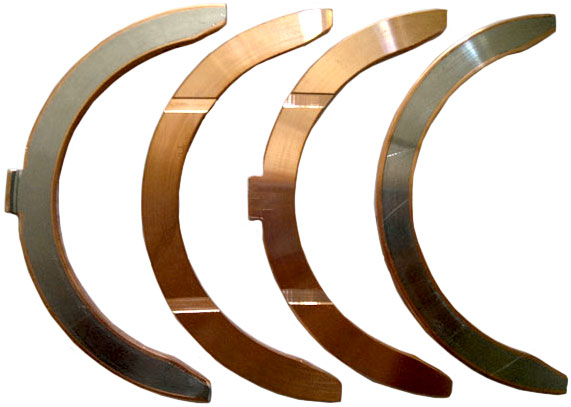

I-Crankshaft thrust half-rings (inkxaso ye-half-rings, iwashers ye-crankshaft, i-crankshaft thrust ethwele i-half-rings) ziibheringi ezikhethekileyo ezithafa ngendlela yesiqingatha-amakhonkco aseka ukusebenza kwe-axial displacement (backlash, clearance) yecrankshaft yokutsha kwangaphakathi. injini.

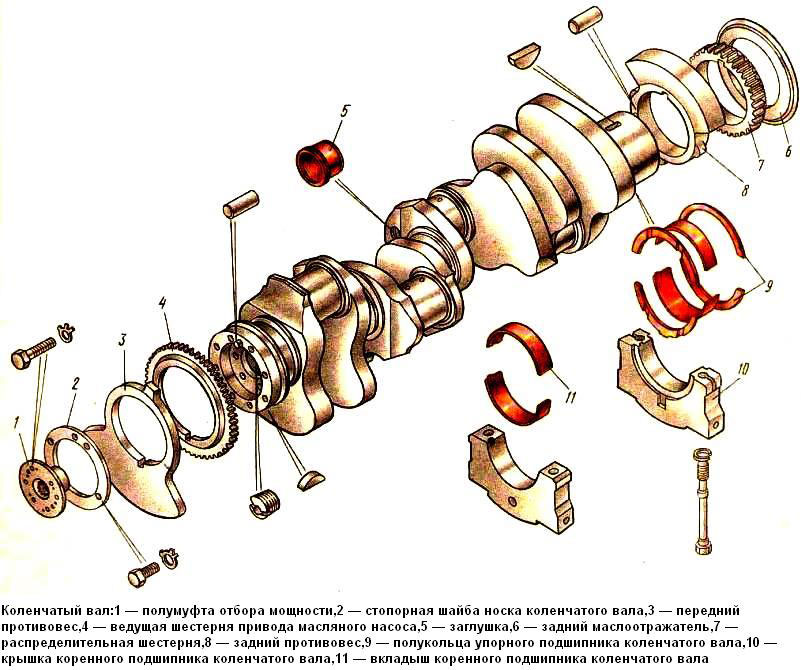

Kwii-injini zokutsha zangaphakathi, ingxaki ye-friction i-acute, ibaluleke kakhulu kwi-crankshaft - kwi-injini yesiqhelo ye-cylinder emine, i-shaft ineendawo ezintlanu zokubhekisela (iijenali eziphambili) kunye nendawo yokudibanisa ngokufanelekileyo.Amandla amakhulu okukhuhlana angenzeka xa imihlathi yeshaft idibana nezixhaso.Ukuze ugweme le meko, iijenali eziphambili ze-crankshaft zenziwe zibanzi kunezixhaso zazo.Nangona kunjalo, isisombululo esinjalo sibangela ukudlala kwe-axial ye-crankshaft, engamkelekanga ngokupheleleyo - ukunyakaza kwe-axial ye-shaft kukhokelela ekunxibeni okunzulu kwamalungu e-crank mechanism kwaye kunokubangela ukuphuka kwabo.

Ukuphelisa i-backlash ye-crankshaft, i-thrust bear ifakwe kwenye yeenkxaso zayo.Le bherethi ihluke kwi-liner yesiqhelo ngobukho beendawo ezinqamlekileyo ze-lateral ngendlela yekhola, amakhonkco akhutshwayo okanye amakhonkco esiqingatha.Ezihlathini ze-crankshaft kwindawo yofakelo yale bheringi, i-thrust annular surfaces zenziwe - zidibene ne-half rings.Namhlanje, zonke iinjini zepiston zixhotyiswe nge-thrust bearings, ngelixa onke amalungu anesakhiwo esifanayo kunye nomgaqo wokusebenza.

Iintlobo kunye noyilo lwe-crankshaft luxhasa i-half-rings

Iintlobo ezimbini zamalungu asetyenziselwa ukunciphisa umdlalo we-crankshaft:

• Gcoba i-half-rings;

• Iiwasha.

Iiwasha ngamakhonkco aneqhekeza elinye axhonywe kwinkxaso yejenali eyintloko yangasemva yecrankshaft.Isiqingatha-amakhonkco ziihafu zamakhonkco axhonywe kwinkxaso yangasemva okanye enye yeejenali eziphambili eziphakathi kwe crankshaft.Namhlanje, imisesane enesiqingatha isetyenziswa kakhulu, njengoko ibonelela ngeyona nto ifanelekileyo kwindawo yokutyhala yecrankshaft kwaye igugile ngokulungeleleneyo, kwaye ikulungele ukufakela / ukudilizwa.Ukongeza, ii-washers zinokufakwa kuphela kwijenali ephambili yangasemva ye-shaft, kwaye iindandatho zesiqingatha zinokufakwa kuyo nayiphi na intamo.

Ngokwesakhiwo, i-half-rings kunye ne-washers zilula kakhulu.Zisekwe kubhedu oluqinileyo okanye isitampu sentsimbi yesiqingatha sentsimbi / isangqa, apho kusetyenziswa i-anti-friction coating, enciphisa ukukhuhlana kwi-thrust surface kumhlathi weshaft.Kwi-antifriction layer, ii-grooves ezimbini okanye ngaphezulu (kwezinye iimeko ze-radial) zenzelwe ukuhamba kwamahhala kweoli.Kwakhona, imingxuma kunye nezikhonkwane zokulungisa iimilo ezahlukahlukeneyo zinokubonelelwa kwindandatho / isiqingatha sokukhusela inxalenye ekujikeni.

Ngokutsho kwezixhobo zokwenziwa kwee-half rings:

• Ubhedu oluqinileyo;

• I-Steel-aluminium - i-aluminium alloy isetyenziswe njenge-antifriction layer;

• I-Metal-ceramic - i-bronze-graphite yokutshiza isetyenziswa njenge-antifriction layer.

I-Bronze isiqingatha-amakhonkco

Intsimbi-aluminiyam isiqingatha-amakhonkco

Intsimbi ye-ceramic isiqingatha-amakhonkco

Namhlanje, intsimbi ye-aluminium kunye ne-ceramic-metal half-rings zisetyenziswa kakhulu, kwaye zihlala zifakwe kwi-injini enye kumacala ahlukeneyo kwijenali yenkxaso.

Izangqa zesiqingatha zineentlobo ezimbini zobukhulu:

• Ngokwesiqhelo;

• Ukulungisa.

Amalungu obungakanani obuqhelekileyo afakwe kwiinjini ezintsha kunye neenjini ezinokuguga okuncinci kumphezulu wokutyhala wecrankshaft kunye nenkxaso.Amalungu obungakanani bokulungisa anobunzima obongeziweyo (ngokuqhelekileyo ngokunyuka kwe-0.127 mm) kwaye ikuvumela ukuba uhlawule ukunxitywa kweendawo zokutyhala ze-crankshaft kunye nenkxaso.

I-crankshaft thrust bearing inokufumaneka kwiijenali zayo ezahlukeneyo:

- Kwenye yeejenali eziphambili (kwiinjini ezine-cylinder - kweyesithathu);

- Entanyeni yangasemva (ukusuka kwicala le-flywheel).

Kule meko, amakhonkco amabini okanye amane anesiqingatha asetyenziswa.Kwimeko yee-half-half-rings, zifakwe kwi-grooves yesigqubuthelo esisezantsi sokuthwala (isigubungelo sejoka).Kwimeko ye-half-half-rings, zifakwe kwi-grooves yesigqubuthelo esisezantsi kunye nenkxaso ephezulu.Kukwakho nee-injini ezinesiqingatha seringi okanye iwasha enye.

Indlela yokukhetha kunye nokutshintsha amakhonkco esiqingatha se-crankshaft?

Ngokuhamba kwexesha, i-half-ring rings, njengazo naziphi na iibheringi ezicacileyo, ziyaguga, ngenxa yoko i-axial play ye-crankshaft iyanda.I-backlash esebenzayo (i-gap) ye-crankshaft ilele kuluhlu lwe-0.06-0.26 mm, ubuninzi - njengomthetho, akufanele budlule i-0.35-0.4 mm.Le parameter ilinganiswa ngokusebenzisa isalathisi esikhethekileyo esifakwe ekupheleni kwe-crankshaft.Ukuba i-backlash idlula ubuninzi obuvumelekileyo, i-thrust half-rings kufuneka itshintshwe.

Iindidi eziphambili ze-diaphragm (i-diaphragm) i-oyile yoxinzelelo lweenzwa

Uluvo luhlobo loqhagamshelwano.Isixhobo sineqela loqhagamshelwano - umfowunelwa oshukumayo obekwe kwi-membrane, kunye noqhagamshelwano olusisigxina oluqhagamshelwe kumzimba wesixhobo.Isikhundla sabafowunelwa sikhethwe ngendlela yokuba kuxinzelelo lweoyile eqhelekileyo kwinkqubo abafowunelwa bavuleleke, kwaye kuxinzelelo oluphantsi bavalwe.Uxinzelelo lomgubasi lusetwa yintwasahlobo, kuxhomekeke kuhlobo kunye nemodeli ye-injini, ngoko ke ii-sensors zohlobo loqhagamshelwano azisoloko zitshintshwa.

Isivamvo seRheostat.Isixhobo sine-rheostat yocingo esisigxina kunye ne-slider exhunywe kwi-membrane.Xa i-membrane itenxa kwi-avareji isikhundla, isilayidi sijikeleza kwi-axis ngokusebenzisa isitulo sokugungqa kunye nesilayidi ecaleni kwe-rheostat - oku kukhokelela ekutshintsheni ukuchasana kwe-rheostat, ebekwe esweni isixhobo sokulinganisa okanye iyunithi yombane.Ngaloo ndlela, ukutshintshwa kwengcinezelo yeoli kubonakaliswe ekutshintsheni ukuchasana kwenzwa, esetyenziselwa imilinganiselo.

Xa ukhetha i-half-rings, kuyimfuneko ukuthathela ingqalelo i-nuance ebalulekileyo: kungekhona nje i-half-rings, kodwa kunye neendawo zokutyhala ze-crankshaft zixhomekeke ekugqokeni.Ngoko ke, kwiinjini ezintsha, xa ukukhutshwa kwe-crankshaft kunyuka, ngokuqhelekileyo kuyimfuneko ukutshintsha amakhonkco angama-half-ephelile kuphela - kule meko, kuyimfuneko ukuthenga iinxalenye zobukhulu obuqhelekileyo.Kwaye kwii-injini ezine-mileage ephezulu, ukunxiba kwe-thrust surface ye-crankshaft kuyaphawuleka - kule meko, kuyimfuneko ukuthenga amakhonkco okulinganisa ubukhulu.

Kuyimfuneko ukuba ukhethe amakhonkco esiqingatha amatsha eentlobo ezifanayo kunye namanani ekhathalogu njengakudala.Kubalulekile ukuba bathobele ngokupheleleyo imilinganiselo yokufakela, kwaye babe ne-anti-friction coating efanelekileyo.Ngokukodwa le meko yokugqibela ibalulekile kwiinjini apho amakhonkco esiqingatha aneengubo ezahlukeneyo zokulwa ne-friction zifakwe ekuqaleni.Ngokomzekelo, kwiinjini ezininzi ze-VAZ, i-semi-ring yangemva i-ceramic-metal, kwaye i-front yintsimbi-aluminiyam, kwaye ayitshintshi.

Ukutshintshwa kwamakhonkco esiqingatha kufuneka kuqhutywe ngokuhambelana nemiyalelo yokugcina nokulungiswa kwemoto.Kwezinye ii-injini, kuyimfuneko ukususa i-pallet kunye nokuqhaqha isigqubuthelo esisezantsi se-thrust bear, kwezinye ii-motor kuya kufuneka ukuba zenze i-disassembly enzima ngakumbi.Xa ufaka amakhonkco amatsha, kuyimfuneko ukugcina i-orientation yabo - i-antifriction coating (apho i-grooves idla ngokubonelelwa ngayo) kufuneka ifakwe kwi-crankshaft cheeks.

Ngokukhetha okufanelekileyo kunye nokufakwa kwesiqingatha-amakhonkco, iibheringi ze-thrust ziya kuqinisekisa ukudlala okuqhelekileyo kwe-crankshaft kunye nokusebenza okuthembekileyo kwayo yonke injini.

Ixesha lokuposa: Aug-21-2023