Ukufakwa kwemithombo kwisakhelo sesithuthi kuqhutyelwa ngoncedo lweenkxaso ezakhiwe kwiindawo ezikhethekileyo - iminwe.Yonke into malunga neminwe yemithombo, iintlobo zabo ezikhoyo, ukuyila kunye neempawu zomsebenzi ekumisweni, kunye nokukhetha okuchanekileyo kweminwe kunye nokutshintshwa kwabo, unokufumana kwinqaku elinikezelweyo.

Yintoni umthombo womnwe?

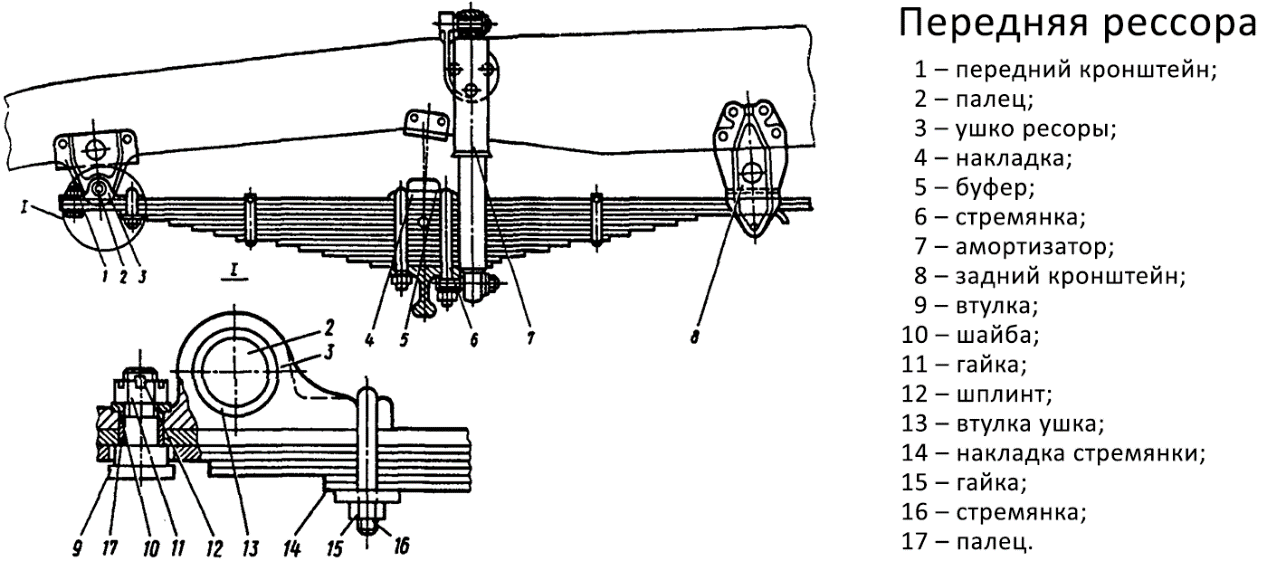

Ukumiswa kwentwasahlobo kunye nendawo yeminwe kuyo

Umnwe wentwasahlobo ligama eliqhelekileyo leenxalenye ngendlela yeentonga ngeendlela ezahlukeneyo zokunyuka (i-threaded, i-wedge, i-pin), ephuma njenge-axles okanye i-fasteners entwasahlobo yokumiswa kwezithuthi.

Ukumiswa kwentwasahlobo, okwasungulwa ngekhulu le-XVIII, kusasebenza kwaye kusetyenziswa ngokubanzi kwindlela yokuthutha.Imithombo isebenza njengezinto ezinwebekayo, ezithi, ngenxa yeempawu zayo eziluhlaza, zikhuphe izothuso kunye nokungcangcazela xa imoto ihamba ecaleni kokungalingani kwendlela.Eyona nto ixhaphakileyo yimithombo ye-semi-elliptical enamanqaku amabini enkxaso kwisakhelo - echazwe kunye ne-sliding.Inqaku elichaziweyo linika amandla okujikeleza intwasahlobo ngokubhekiselele kwisakhelo, kwaye indawo ye-sliding inikezela utshintsho kubude bentwasahlobo ngexesha lokuguqulwa okwenzeka ngexesha lokunqoba ukungalingani kwendawo yendlela.I-axis yenkxaso echazweyo, ekhoyo phambi kwentwasahlobo, yinto ekhethekileyo - umnwe wendlebe yasentwasahlobo (okanye umnwe wecala langaphambili lentwasahlobo).Izixhaso zangasemva ze-sliding spring zihlala zenziwe kwiibholiti kunye namanye amalungu, kodwa ngamanye amaxesha iminwe yoyilo olwahlukeneyo isetyenziswa kuzo.

Iminwe yasentwasahlobo zizinto ezibalulekileyo zokunqunyanyiswa ezihlala zisebenza phantsi kwemithwalo ephezulu (nangona xa imoto ingashukumi), ngoko ke ixhomekeke ekunxibeni okukhulu kwaye ngamanye amaxesha ifuna ukutshintshwa.Kodwa ngaphambi kokuthenga iminwe emitsha, kufuneka uqonde ukuyila kunye neempawu zala malungu.

Iintlobo, uyilo kunye neempawu zemithombo yeminwe

Ukufaka umnwe wentwasahlobo kwi-nut

Iminwe yemithombo ihlelwa yimisebenzi eyenziwa ekumisweni (kwaye, ngokufanelekileyo, ngendawo yokufakela), kunye nendlela yokufakela.

Ngokwenjongo (imisebenzi), iminwe yahlulwe yangamaqela amathathu aphambili:

● Iminwe yendlebe (isiphelo sangaphambili) sentwasahlobo;

● Iminwe yokuxhasa ngasemva kwentwasahlobo;

● Iminwe eyahlukeneyo yokufaka.

Phantse kuzo zonke iqabunga lokumiswa kwentwasahlobo kukho umnwe wendlebe, eyona nto iphambili kwihinge yangaphambili ye-fulcrum yangaphambili nasemva kwemithombo.Lo mnwe wenza imisebenzi emininzi:

● Isebenza njenge-axis (kingpin) yefulcrum echaziweyo;

● Ukubonelela ngoqhagamshelo lomatshini lwendlebe yasentwasahlobo kunye nesibiyeli esibekwe kwisakhelo;

● Ukubonelela ngokugqithiselwa kwemikhosi kunye neetorque ukusuka kwivili ukuya kwisakhelo sesithuthi.

Izikhonkwane zenkxaso yangasemva azifumaneki kuzo zonke iintambo zentwasahlobo, ngokuphindaphindiweyo le nxalenye ithathelwa indawo ngamabholithi okanye izibiyeli ngaphandle kwezibophelelo ezinentambo.Le minwe inokohlulwa ibe ziindidi ezimbini eziphambili:

● Iminwe enye igxininiswe kwiibhakethi zangasemva zentwasahlobo (ngokuchanekileyo, kwiifakelo ze-bracket);

● Iminwe emibini iqokelelwe kwicici.

Iminwe enye esetyenziswa ngokuqhelekileyo ifumaneka kwi-bracket yangasemva, intwasahlobo iphumle kulo mnwe (ngokuthe ngqo okanye nge-gasket ekhethekileyo eqinile).Iminwe emibini isetyenziswa kancinci, kwaye ngokuqhelekileyo kwiimoto ezinobunzima obuncinci (umzekelo, kwezinye iimodeli ze-UAZ).Iminwe iqokelelwa ngababini ngoncedo lweepleyiti ezimbini (izihlathi), ukwenza i-ecici lokuxhoma entwasahlobo: umnwe ophezulu wecici ufakwe kwisibiyeli kwisakhelo, umnwe ongezantsi - endlebeni ngasemva. intwasahlobo.Le ntaba ivumela isiphelo esingasemva sentwasahlobo ukuba sitshintshe kwiinqwelo-moya ezithe tye nezithe nkqo xa ivili lihamba ngeendlela ezingalinganiyo.

Iindidi ezahlukahlukeneyo zezikhonkwane zokukhwela zisetyenziselwa ukudibanisa ipakethe yeeplate zasentwasahlobo kwindlebe (okanye ipleyiti yeqabunga, ekupheleni kwayo i-loop yenziwe).Zombini iminwe kunye neebholiti zingasetyenziselwa ukudityaniswa ngokudityaniswa neeplastiki ezahlukeneyo kunye ne-rubber bushings.

Ngokwendlela yokufakela, iminwe yemithombo yohlulwe ibe ziindidi ezintathu:

1. Ngokulungiswa kunye neebholiti ezinqamlekileyo zobubanzi obuncinci (i-jamming);

2. Ngokulungiswa kwamantongomane;

3. Ngokulungiswa kwephini.

Iindlebe zeminwe ziphuma ngokulungiswa kunye neebholithi ezimbini

Iindlebe zeminwe ziphuma ngokulungiswa nge nut

Umnwe wenkxaso yangasemva yentwasahlobo kwiphini

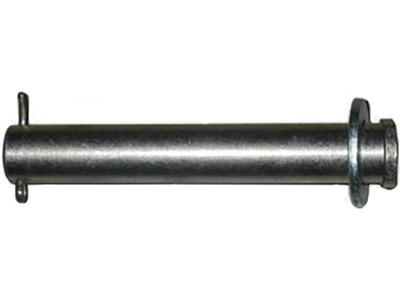

Kwimeko yokuqala, kusetyenziswa umnwe we-cylindrical, kwindawo esecaleni apho iinotshi ezimbini ezinqamlezileyo ze-semicircular zenziwe.Isibiyeli sineebholithi ezimbini ezinqamlezileyo ezingena kwiinotshi zomnwe, ziqinisekisa ukuxinana kwayo.Ngolu fakelo, umnwe ugcinwe ngokukhuselekileyo kwi-bracket, ayijikelezi malunga ne-axis kwaye ikhuselwe ekuweni phantsi kweempembelelo zemithwalo yokuthuthumela kunye nokunyakaza.Iminwe yolu hlobo isetyenziswa kakhulu kwiilori, kuquka iilori zasekhaya ze-KAMAZ.

Kwimeko yesibini, intambo inqunyulwa ekupheleni komnwe, apho i-nuts enye okanye ezimbini ezine-thrust washers zifakwe kuyo.Zombini amandongomane aqhelekileyo kunye namandongomane esithsaba angasetyenziswa aphelele ngepini efakwe kumngxunya onqamlezayo emnweni, kwaye ibala ngokuthembekileyo i-nut.

Kwimeko yesithathu, iminwe isetyenzisiwe, igxininiswe kuphela ngepini, esebenza njengento yokumisa ekhusela inxalenye ukuba ingaweli kwi-bracket.Ukongezelela, i-washer ye-thrust isetyenziswa kunye nephini.

Iminwe yodidi lokuqala kunye neyesibini isetyenziswe kwiinkxaso zangaphambili zemithombo, iminwe yodidi lwesithathu - kwiinkxaso zangasemva zemithombo.

Kwiqela elihlukeneyo, unokukhupha iminwe esetyenziswe kumacici emithombo.Kwesinye isihlathi, iminwe icinezelwe, apho ukwandiswa ngenotshi ye-longitudinal kwenziwa phantsi kweentloko zabo - umnwe ufakwe emngxunyeni esihlathini kunye nolu lwandiso, kwaye luqiniswe ngokungqongqo kuyo.Ukudibanisa kunye nesihlathi sesibini kuqhutyelwa ngamantongomane aqhelekileyo okanye amantongomane esithsaba ngezikhonkwane.Ngenxa yoko, uxhulumaniso oluqhekezayo lwenziwa, ngenxa yokuba i-earring inokunyuswa ngokulula kwaye ikhutshwe, kwaye ukuba kuyimfuneko, idibaniswe ukuze ithathe indawo yomunwe omnye.

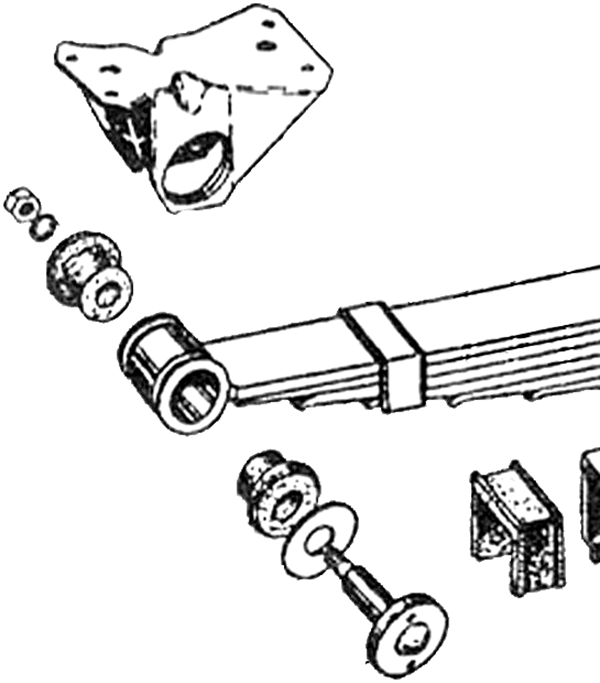

Ukufakwa kweminwe yenkxaso yangaphambili kwiibrakethi kuqhutyelwa ngomkhono oqinileyo okanye odibeneyo.Kwiilori, i-bushings yensimbi eqinile idla ngokusetyenziswa rhoqo, apho iminwe ifakwe kwii-rubber ring seal (cuffs).Kwiimoto ezikhanyayo, i-bushings edibeneyo equkethe i-rubber bushings edibeneyo kunye namagxa adityaniswe yi-bushings yentsimbi yangaphandle nangaphakathi isetyenziswa ngokubanzi - olu yilo luyi-hinge ye-rubber-metal (ibhloko ethuleyo), eyanciphisa inqanaba elipheleleyo lokungcangcazela kunye nengxolo yokumiswa.

Ukusebenza okuqhelekileyo komnwe wenkxaso yangaphambili (indlebe yasentwasahlobo), i-lubrication yayo iyimfuneko - ngenxa yale njongo, umjelo owenziwe ngu-L wenziwa kwiminwe (ukugaya ekupheleni nakwicala elisecaleni), kunye nomgangatho oqhelekileyo. i-oiler press ifakwe ekupheleni kwintambo.Ngokusebenzisa i-oiler, igrisi iphonswa kumjelo womnwe, ongena kwi-bushing kwaye, ngenxa yoxinzelelo kunye nokufudumala, isasazwa kulo lonke isithuba phakathi kwe-bushing kunye nomnwe.Ukusasazwa ngokulinganayo kwe-lubricant (kunye nofakelo oluchanekileyo lwenxalenye kwisibiyeli), iinotshi zelongitudinal kunye neziguquguqukayo zeemilo ezahlukeneyo zinokwenziwa emnweni.

Indlela yokuthatha kunye nokubuyisela imithombo yeminwe

Ngethuba lokusebenza kwesithuthi, yonke iminwe yemithombo ixhomekeke kwimithwalo ebalulekileyo yemishini, kunye nemiphumo emibi yendalo engqongileyo, ekhokelela ekugqokeni kwabo okunzulu, ukuguqulwa kunye nokubola.Hlola imeko yeminwe kunye ne-bushings yabo kufuneka ibe kwi-TO-1 nganye, ngexesha lokuhlola kuyimfuneko ukuvavanya ngokubonakalayo kunye nesixhobo sokuvavanya ukunxiba kweminwe kunye ne-bushings, kwaye, ukuba kukhulu kunokuba kuvunyelwe, tshintsha la macandelo.

Kuphela loo minwe kunye namalungu ahambelanayo acetyiswa ngumenzi wesithuthi kufuneka athathelwe ukutshintshwa.Ukusetyenziswa kwezinye iintlobo zamacandelo kunokukhokelela ekugqokeni kwangaphambi kwexesha kunye nokuphulwa kokumiswa, umphumo ombi unokuphinda ube nokuveliswa okuzimeleyo kweminwe (ingakumbi ukuba ibakala lensimbi likhethwe ngokungalunganga).Kufuneka utshintshe umnwe wentwasahlobo ngokuhambelana nemiyalelo yokulungiswa nokugcinwa kwesithuthi.Ngokuqhelekileyo lo msebenzi wenziwa ngolu hlobo lulandelayo:

1. Xhoma inxalenye yemoto ukusuka kwicala lomthombo ukuze ulungiswe, ukhulule umthombo;

2. Nciphisa i-absorber yokothuka entwasahlobo;

3. Ukukhulula umnwe - ukhulule i-nut, ukhulule iibhotshi, ususe ipini okanye wenze eminye imisebenzi ngokuhambelana nohlobo lokuqhotyoshelwa komnwe;

4. Susa umnwe - uwubethe okanye uwukhuphe ngaphandle komkhono ngesixhobo esikhethekileyo;

5. Hlola i-bushing kwaye, ukuba kuyimfuneko, yisuse;

6. Fakela amalungu amatsha, sele ugqibile ukwenza i-lubrication;

7. Ukubuyisela umva ukwakha.

Kufuneka kuqatshelwe ukuba kwezinye iimeko, unako ukususa umnwe kuphela ngoncedo lwabatsali abakhethekileyo - esi sixhobo kufuneka sithathelwe ingqalelo kwangaphambili.Umtsalani unokuthengwa okanye wenziwa ngokuzimeleyo, nangona iimveliso zefektri zisebenza ngokufanelekileyo.

Emva kokutshintsha umnwe, kuyimfuneko ukuyigcwalisa ngegrisi ngokusebenzisa i-oiler ye-press, kwixesha elizayo ukwenza lo msebenzi ngokulungiswa okufanelekileyo.

Ukuba umnwe wentwasahlobo ukhethiwe kwaye utshintshwe ngokuchanekileyo, ukumiswa kwemoto kuya kusebenza ngokuthembekileyo kuzo zonke iimeko, ukubonelela ngokukhululeka kunye nokuhamba ngokukhuselekileyo.

Ixesha lokuposa: May-06-2023