Kwiibhuleki zesondo zeemoto ezininzi zanamhlanje kukho icandelo elibonelela ngokulungiswa kunye nokukhuselwa kwamacandelo - i-brake shield.Konke malunga nesikhuselo se-brake, imisebenzi yayo ephambili kunye noyilo, kunye nokugcinwa kunye nokulungiswa kwale nxalenye, unokufunda kwinqaku.

Yintoni ikhaka lokuqhobosha?

I-Brake shield (ikhaka, isikhuselo sokukhusela, isikrini sokukhusela) - inxalenye yeebhuleki zevili zezithuthi ezinamavili;Inxalenye yentsimbi ngendlela yekhuselo okanye i-semicircular shield ebambe ezinye iindawo ze-brake mechanism kwaye ikhusele ekungcoleni, umonakalo womatshini kunye neempembelelo ezimbi zokusingqongileyo.

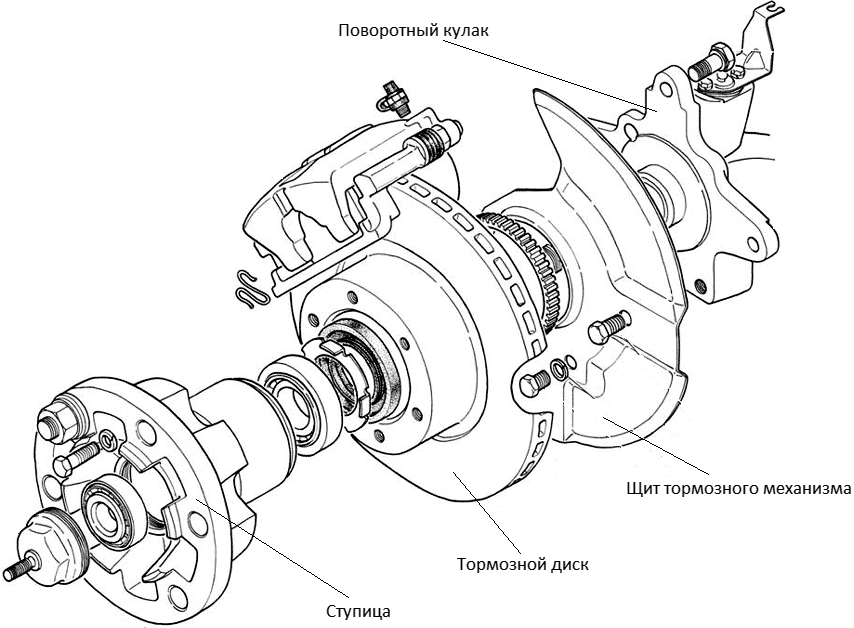

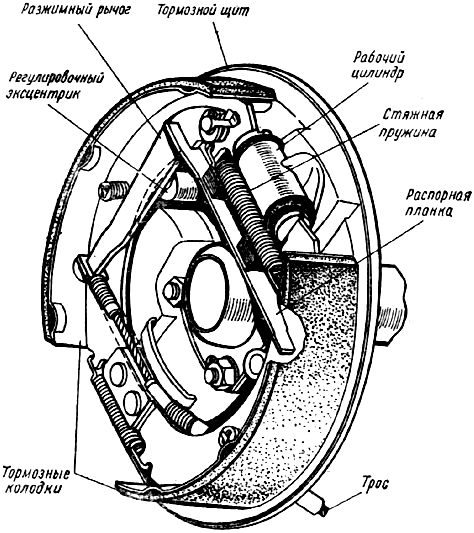

Zonke iinqwelo zamavili zala maxesha zixhotyiswe ngeziqhoboshi zohlobo lwe-friction ezibekwe ngqo kwi-asi yamavili.Ngokwemveli, iziqhoboshi zamavili zineenxalenye ezimbini: ezishukumayo, eziqhagamshelwe kwi-hub yevili, kwaye zilungisiwe, ezinxulunyaniswa neqhosha lokuqhuba (kumavili aqhubayo angaphambili), iindawo zokunqunyanyiswa okanye i-axle beam flange (ngasemva nangamavili angaqhutywanga).Inxalenye eshukumayo yesixhobo ibandakanya idrum yebhuleki okanye idiski edityaniswe ngokungqongqo kwi-hub kunye nediski yevili.Kwinxalenye emiselweyo kukho iipads eziqhekezayo kunye ne-drive yazo (iisilinda, i-caliper kunye ne-cylinders kwi-disc brakes), kunye nenani leengxenye ezincedisayo (i-parking brake drive, iintlobo ezahlukeneyo zeenzwa, izinto zokubuya kunye nabanye).Amalungu asisigxina abekwe kwindawo ekhethekileyo - ikhuselo (okanye i-casing) ye-brake.

Ikhaka libekwe ngaphakathi kwindlela yokuqhawuka kwevili, idityaniswe ngokuthe ngqo kwi-knuckle yokuqhuba, ibhulorho yeflange okanye iindawo zokumiswa, imisebenzi emininzi eyabelwe yona:

● Umsebenzi wesiqalelo samandla kukubamba amalungu angatshintshiyo omatshini wevili, ukuqinisekisa indawo yawo echanekileyo kuzo zonke iindlela zokusebenza zeziqhoboshi;

● Umsebenzi welungu lomzimba kukukhusela iinxalenye zendlela ye-brake ekungeneni kokungcola komatshini omkhulu kunye nezinto zangaphandle, kunye nokukhuselwa kwazo kumonakalo womatshini ngenxa yokudibanisa nezinye iindawo zesakhiwo semoto kunye nezinto zangaphandle;

● Imisebenzi yenkonzo - ukunika ufikelelo kwizinto eziphambili zohlengahlengiso lwesixhobo sokwenza ugcino kunye nokuhlolwa okubonakalayo kweebhuleki.

Isikhuseli se-brake asiyona inxalenye ebalulekileyo ekusebenzeni kweebhuleki, nangona kunjalo, ukuba le nxalenye iyancipha okanye ilahlekile, iibhuleki zixhomekeke ekugqokeni okukhulu kwaye zinokungaphumeleli ngexesha elifutshane.Ngoko ke, ukuba kukho naziphi na iingxaki kunye nekhaka, kufuneka litshintshwe, kwaye ukwenzela ukuba ukulungiswa ngokuchanekileyo, kuyimfuneko ukuqonda ukuyila kunye neempawu zala macandelo.

Isixhobo se-disc brake mechanism kunye nendawo yekhuselo kuyoUyilo lomatshini wokuqhawula igubu kunye nendawo yekhaka kuyo

Iintlobo kunye noyilo lwezikhuselo ze-brake

Kwiimoto kunye neenqwelo ezahlukeneyo ezinamavili, izikhuselo zebhuleki ezifanayo ngokusisiseko kuyilo zisetyenziswa: le yinxalenye yentsimbi enesitampu ngohlobo lwesangqa okanye semicircle, apho imingxuma eyahlukeneyo, i-niches kunye nezinto ezincedisayo zenziwa ukuze kufakwe izinto zebrake. .Ngokuqhelekileyo, ikhaka ligqunywe ngepeyinti emnyama, ekhusela inxalenye kwi-corrosion.Iinkcukacha ezahlukeneyo zinokufumaneka kwikhaka:

● Umngxuma osembindini we hub yevili okanye i-axle shaft;

● Imingxuma yokunyuka - yokuxhoma ikhaka kwindawo esisigxina yokumiswa;

● Ukujonga iifestile - ukufikelela kwiindawo ze-brake mechanism ngaphandle kokuqhaqha ivili kunye nekhuselo ngokwalo;

● Imingxuma yokuqhoboshela iindawo zesixhobo sokuqhobosha;

● Iihenjisi kunye nezibiyeli zokulungisa imithombo yamanzi kunye nezinye iindawo zomatshini;

● I-bushings ecinezelweyo yokufaka iintambo, ukufaka ii-axes ze-levers, i-sensors kunye nezinye iindawo;

● Amaqonga kunye neendawo zokumisa zokubeka iziko kunye nokuqhelaniswa okuchanekileyo kwamalungu.

Kwangaxeshanye, kukho iintlobo ezimbini zezikhuselo zebrake ngokwemigaqo yokusebenziseka: kwidisc kunye neziqhoboshi zegubhu.Banoyilo olwahlukileyo, olukwaxhomekeke kwindawo - kumavili aqhuba ngaphambili, kumavili okuqhuba angasemva okanye kumavili e-asi eqhutywa ngasemva.

Ngokwesakhiwo, izihlangu zangaphambili kunye namavili angasemva eemoto ezineebhuleki zediski zezona zilula.Enyanisweni, i-casing yesitampu yensimbi, ifakwe kwi-knuckle yokulawula (phantsi kwe-hub) okanye kwizinto ezimisiweyo zokumisa, kwaye ithatha imisebenzi yokukhusela kuphela.Njengomthetho, kuphela umngxuma ophakathi, inani lemingxunya ekhulayo kunye nokusika okubonakalayo kwenxalenye ye-caliper ephuma ngaphakathi kwevili yenziwe kule nxalenye.

Okuntsonkothe ngakumbi ngamakhaka awo onke amavili aneziqhoboshi zegubu.Yonke indlela ibekwe kwi-casings enjalo - i-cylinder ye-brake (okanye iisilinda), iipads, iinxalenye ze-pad drive, imithombo, izinto zokupaka i-brake drive, ukulungiswa kwezinto kunye nabanye.Ikhaka linomngxuma ophakathi kunye nemingxuma yokunyuka, ngoncedo apho yonke indibano ifakwe kwi-flange ye-axle ye-drive beam okanye izinto zokumiswa.Olu hlobo lwenxalenye luneemfuno ezinzulu zokomelela kunye nokuqina, njengoko ludlala indima ebalulekileyo ekusebenzeni kwayo yonke indlela yokuqhawula.Ke ngoko, yenziwe ngentsimbi eyomeleleyo kunye netyebileyo, ihlala inezigxina (kubandakanywa nebhodi ye-annular ejikeleze umjikelezo wekhaka) kunye nezinto ezincedisayo zokuqinisa.

Ekugqibeleni, kufuneka kuqatshelwe ukuba izikhuselo ze-brake ziqinile kwaye zidibeneyo.Kwimeko yokuqala, yinxalenye enye isitampu, okwesibini - a prefabricated inxalenye ezimbini (isiqingatha amakhonkco).Ngokuqhelekileyo, amacandelo asetyenziswa kwiilori, aququzelela ukufakwa, ukugcinwa kunye nokulungiswa kweebhuleki, kwaye kwimeko yomonakalo, kwanele ukutshintshela isiqingatha esinye kuphela, esinciphisa iindleko.

Imiba yogcino, ukukhetha kunye nokutshintshwa kwezikhuselo zebrake

Isikhuseli se-brake asifuni ukugcinwa okukhethekileyo ngexesha lokusebenza kwesithuthi - kufuneka sihlolwe kwindawo nganye yokugcina iibhuleki, kwaye, ukuba kuyimfuneko, ihlanjululwe kwizinto ezingcolileyo.Ukuba ikhaka lonakaliswe okanye likhubazekile (ingakumbi i-drum brake shield), kuyacetyiswa ukuba ithathe indawo yayo.Ukulungiswa, kuyimfuneko ukusebenzisa inxalenye yohlobo olufanayo kunye nenombolo yekhathalogu efakwe ngaphambili.Ngaphezu koko, kufuneka kukhunjulwe ukuba izihlangu azikho kuphela ngaphambili nangemuva, kodwa zilungile nasekhohlo.

Ukutshintshwa kwenxalenye kufuneka kuqhutywe ngokuhambelana nemiyalelo yokulungiswa nokugcinwa kwesi sithuthi.Ngokuqhelekileyo, lo msebenzi uphantsi kokulandelayo:

1.Phakamisa imoto ngejekhi (emva kokuyibhuqa kunye nokuqinisekisa ukungahambi);

2.Susa ivili;

3.Dismantle i-drum ye-brake okanye i-disc kunye ne-caliper (oku kunokufuna inani lemisebenzi yokuncedisa - ukuphula idramu ukusuka esihlalweni ngokukrazula kwi-screws, kunye nabanye);

4.Dismantle i-hub yevili (kwi-disc brakes, i-hub ivame ukususwa kunye nekhaka);

5.Dismantle isikhuseli se-brake kunye nazo zonke iindawo ezifakwe kuyo (oku kunokufuna isitshixo esikhethekileyo, kwaye ukufikelela kwii-fasteners kudla ngokuvulwa kuphela ngemingxuma ekhethekileyo kwi-hub).

Isikhuseli seBrake esineendawo ezifakelweyo zokuqhobosha

Ukuba imoto ene-disc brakes iyalungiswa, ke wonke umsebenzi uyancitshiswa ukutshintshwa kwe-casing elula.Emva koko, yonke i-node ihlanganiswe ngokulandelelana.Ukuba umsebenzi uqhutyelwa kwimoto kunye neebhuleki zegubhu, ngoko emva kokuqhawula isihlangu, kuyimfuneko ukususa iindawo eziqhekezayo kuyo, zifake kwisihlangu esitsha, kwaye emva koko udibanise kwakhona.Emva kokulungiswa, kuyimfuneko ukwenza yonke imisebenzi yokulawula i-hub bear (ukuba ibonelelwe), kunye nokugcina kunye nokulungelelanisa inkqubo ye-brake yemoto.

Uyabona ukuba ukutshintshwa kwekhaka le-brake kubonakala kulula - ngenxa yoko kufuneka udibanise ngokupheleleyo ivili kunye neendlela ezikuyo.Ngoko ke, kuyimfuneko ukukhetha inxalenye efanelekileyo kwaye wenze ukulungiswa ngokuhambelana nazo zonke iingcebiso ze-automaker.Ukuba impazamo yenziwe, ngoko kuya kuthatha ixesha elininzi kunye nomgudu ukuyilungisa.Isiphumo esithembekileyo sinokufezekiswa kuphela ngokuthengwa okufanelekileyo kwamacandelo angasese kunye nendlela echanekileyo yokulungisa umsebenzi.

Ixesha lokuposa: Jul-12-2023