I-Shafts ephuma kwiiyunithi zokuhambisa kunye nezinye iindlela zemoto zingabangela ukuvuza kunye nokungcoliswa kweoli - le ngxaki isonjululwe ngokufaka izitywina zeoli.Funda konke malunga nezitywina zokuqhuba, ukuhlelwa kwazo, ukuyila kunye nokusebenza, kunye nokukhetha okuchanekileyo kunye nokutshintshwa kwezitywina kwinqaku.

Yintoni i-oyile yokutywina?

Ukutywinwa kweoli ye-oyile (i-cuff) - into yokutywinwa kweeyunithi ezahlukeneyo kunye neenkqubo zezithuthi;isangqa esidibeneyo esiqinisekisa ukutywinwa kwee-shafts, iibheringi kunye nezinye iindawo ezijikelezayo kwiindawo zokuphuma kwazo kumzimba weyunithi.

Kuyo nayiphi na imoto, itrektara kunye nezinye izixhobo kukho iiyunithi kunye neendlela, ukusuka kumzimba apho i-shafts ejikelezayo iphuma - iibhokisi zegiya, iibhokisi zegiya, ii-fan drives kunye nabanye.Ngokuqhelekileyo kukho ioli okanye enye i-lubricant ngaphakathi kwezi yunithi, kwaye umngxuma we-shaft unokubangela ilahleko kunye nokungcoliswa kwe-lubricant.Ingxaki yokutywinwa kokuphuma kwee-shafts ezijikelezayo ngaphandle kwezindlu zeeyunithi zixazululwa ngoncedo lwezinto ezikhethekileyo zokutywinwa - izitywina (ii-cuffs) zokuqhuba.

Isitywina seoyile yokuqhuba yenza imisebenzi emininzi:

● Ukuthintelwa kokuvuza kwe-oyile kunye nokulahleka kwesinye isithambisi kumzimba weyunithi okanye isixhobo;

● Ukukhuselwa komatshini kumanzi, uthuli nezingcolisi ezinkulu;

● Ukukhuselwa kwesithambiso ekungcolisweni ngumbhobho womoya kunye nezinye iigesi.

Ukwaphulwa kwengqibelelo okanye ukulahlekelwa kwetywina leoli kukhokelela ekuvuzeni okukhulu kweoli kunye nokungcoliswa kwayo, okuza kuthi kungekudala kubangele ukuchithwa kweyunithi yonke.Ukuthintela oku, isibonelelo esiphelelwe lixesha okanye isitywina esinempazamo kufuneka sitshintshwe ngexesha elifanelekileyo.Ukukhethwa okuchanekileyo kunye nokutshintshwa kwezinto zokutywinwa, kuyimfuneko ukuqonda iintlobo zabo ezikhoyo, ukuyila kunye nokusebenza.

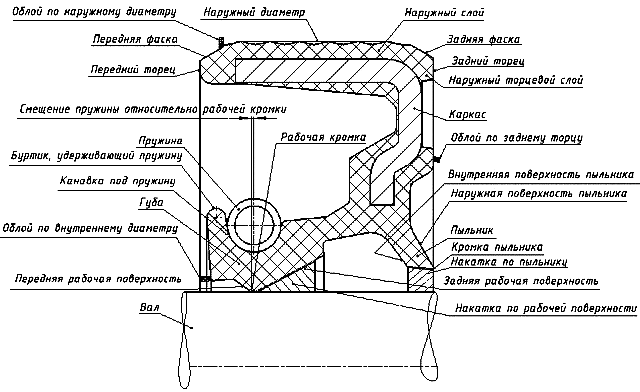

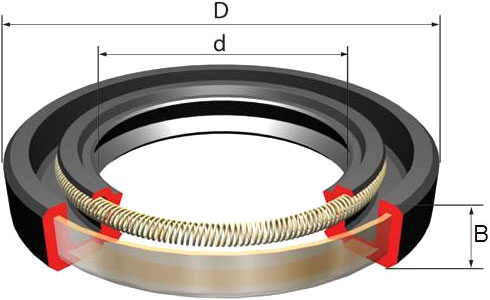

Uyilo lwetywina lokuqhuba oluqhelekileyo

Iintlobo, uyilo kunye neempawu zokutywinwa kwedrive

Onke amatywina e-oyile enziwa ngohlobo lwendandatho eneprofayili emile okwe-U, apho imiphezulu emithathu igqamile:

● Ngaphakathi okanye ukusebenza - iquka imiphetho yokusebenza, lo mphezulu we-oyile ye-oyile uhlala kwi-shaft;

● Ingaphandle - igudileyo okanye i-grooved, lo mphezulu we-oyile ye-oyile udibana nomzimba weyunithi;

● Isiphelo - ngokuqhelekileyo sicaba, lo mphezulu uhambelana nomzimba weyunithi.

I-cuff ifakwe kwisihlalo kumzimba weyunithi (ibhokisi ye-oyile yokutywinwa) kwaye iphumle kwi-shaft, ngenxa yoyilo, ukuqina kwayo okuqinileyo kumzimba kunye ne-shaft kuyaqinisekiswa, okufezekisa ukutywinwa.

Izitywina zeoyile zahlulwe zaba ziindidi ezininzi ngokobukho / ukungabikho kwezinto ezahlukeneyo kunye neempawu zomsebenzi.

Okokuqala, amatywina e-oyile ahlulwe abe ziindidi ezimbini ngokoyilo:

● Ingenasakhelo;

● Ngesakhelo sokuqinisa.

Uyilo lwetywina olungaqiniswanga kunye nentwasahlobo

Ukwakhiwa kunye nemilinganiselo esisiseko yetywina yeoli eqinisiweyo kunye nentwasahlobo

Iimpawu ze-oyile zohlobo lokuqala zenziwe ngendlela ye-ring elastic ye-rubber yokwenziwa, kwindawo engaphakathi apho imida yokusebenza yenziwe.Njengomgangatho, imiphetho emibini yokusebenza inikezelwa kwiimpawu zeoli - ngaphambili nangasemva, kodwa inani labo linokufikelela ezine.Ngaphakathi kwindandatho kukho i-coil spring ephothiweyo eqengqeleke kwindandatho, enika i-clamping eqinileyo yesitywina seoli ukuya kwi-shaft.

Izitywina zodidi lwesibini zinzima ngakumbi - ngaphakathi kwindandatho kukho isakhelo sokuqinisa intsimbi yefom enye okanye enye.Amaxesha amaninzi, isakhelo sithe tye (ipleyiti eqengqeleke kwindandatho) okanye iprofayili emile okwe-L, kodwa kukho izitywina zeoyile ezinezakhelo zeprofayili enzima ngakumbi.Ngaphandle koko, iinxalenye eziqinisiweyo zifana nezo zingaqiniswanga.

Izitywina zeoyile ezinesakhelo sokuqinisa zohlulwe zibe ziindidi ezintathu zesakhiwo:

● Ngesakhelo esivaliweyo;

● Ngesakhelo esivezwe ngokuyinxenye;

● Ngesakhelo esingenanto.

Kuyilo lohlobo lokuqala, isakhelo sibekwe ngokupheleleyo ngaphakathi kwindandatho yerabha yesitywina seoli, okanye ikhonkco igubungela ngokupheleleyo umphezulu wangaphandle wesakhelo.Kwimeko yesibini, ikhonkco igubungela isiphelo kunye nenxalenye yendawo yangaphandle yesakhelo, kwaye kwimeko yesithathu, isakhelo siphantse sivuleke ngokupheleleyo.Izitywina ezinesakhelo sokuqinisa ngokuyinxenye kwaye esingenanto ngokupheleleyo zifakwe ngokuqinileyo kwisihlalo sazo, kuba ziphumla kumzimba wesinyithi weyunithi enentsimbi yentsimbi.Nangona ezo zitywina zibonelela ngesitywina esibi kakhulu, okwenza kube yimfuneko ukusebenzisa ama-sealants okanye iindawo ezongezelelweyo.

Iringi elastiki yazo zonke iintlobo zeoli ye-oyile inokwenziwa ngeentlobo ezahlukeneyo zerubha yokwenziwa - i-acrylate, irabha ye-fluoro, i-butadiene-nitrile, i-silicone (i-organosilicon) kunye nabanye.Ezi zixhobo zinokumelana okungalinganiyo kumaqondo okushisa aphezulu kunye aphantsi kunye ne-lubricant, kodwa zinee-coefficients ezifanayo ze-friction kwintsimbi kunye namandla omatshini.

Amatywina okuqhuba anokuba nezinto ezahlukeneyo ezongezelelweyo:

● I-anther yintsinjana encinci engaphambili kwindandatho ethintela ungcoliseko olukhulu (amatye, imisonto, iitshiphusi, njl. njl.) ukuba zingangeni kwitywina leoli.I-anther inokucinezelwa ngokuchasene ne-shaft ngenxa ye-elasticity yayo okanye ngoncedo lwentwasahlobo eyongezelelweyo edibeneyo;

● Ukugrunjwa komphezulu ongaphandle - ukugoba kwimilo elula okanye entsonkothileyo, ephucula ukulingana kwesitywina seoli kwaye ithintele ukuvuza kweoli ngesantya esiphezulu naxa ubushushu buphakama;

● I-Hydrodynamic knurling kunye neenotshi kumphezulu wangaphakathi (osebenzayo).Iinotshi ezidayiweyo zifakwe kwi-engile ethile kwi-axis yesitywina se-oyile, ukuthintela ukuvuza kwe-oyile ngesantya esiphezulu seshaft.Iinotshi zinokwenziwa phezu komhlaba wonke wangaphakathi, okanye ngendlela yeendandatho ezininzi kumphezulu osebenzayo kunye nemiphetho yokusebenza.

Amatywina e-oyile ahlulwe abe ngamaqela amabini kwicala lokujikeleza kwe-shaft:

● Kwi-shafts enesikhokelo esiqhubekayo sokujikeleza;

● Kwi-shafts ezinokujikeleza okubuyela umva.

Izitywina ngeenjongo ezahlukeneyo ziyahluka ngohlobo lwe-knurling okanye iinotshi kumphezulu wokusebenza.Kwiimpawu zeoli ze-shafts kunye nolwalathiso oluqhubekayo lokujikeleza, i-knurling yenziwe ngendlela yokuqhafaza ejoliswe kwelinye icala, ngoko ke iindawo ezinjalo zine "right" kunye ne "left" knurlings (notches).Kwii-omentums ezibuyiselwa umva, inotshi i-zigzag okanye intsonkothe ngakumbi ngokwemilo.

Uyilo lwedlala lekhasethi

Okokugqibela, izitywina zokuqhuba ziziindidi ezimbini ngokwemiqathango yokhuseleko:

● Eqhelekileyo (eqhelekileyo);

● Ikhasethi.

Iimpawu zeoli eziqhelekileyo zinoyilo oluchazwe ngasentla.Iimpawu zeCassette zenziwe ngendlela yamakhonkco amabini afakwe enye kwenye (i-ring yangaphandle ixhomekeke emzimbeni weyunithi kwaye iphumle kwi-shaft, i-ring yangaphakathi iphumle ngaphandle kwaye iphumle ngokuyinxenye kwi-shaft) - olu luyilo luyamelana. imithwalo ebalulekileyo yoomatshini kwaye ibonelela ngokhuseleko olungcono ekungeneni kwezinto ezingcolileyo.Amatywina ekhasethi asetyenziswa kwiiyunithi ezisebenza kwiimeko zokunyuka kothuli kunye nongcoliseko.

Ukuqukumbela, siyaqaphela ukuba kwiimoto, iitrektara kunye nezinye izixhobo, ukutywinwa kwee-drive ezahlukeneyo zisetyenziselwa injongo yazo: i-semi-axles yamavili, i-gearbox shafts kunye ne-gearbox, i-fan drive shafts kunye nabanye.Kodwa uninzi lwamacandelo lubekwe kuthumelo, apho bafumana igama labo.

Indlela yokukhetha kunye nokubuyisela uphawu lweoli ye-drive

Amatywina okuqhuba afumana imithwalo ebalulekileyo, ethi ekuhambeni kwexesha iholele ekunxibeni, ukonakala okanye ukutshatyalaliswa ngokupheleleyo kwesitywina.Xa ukuvuza kweoli kubonakala, isitywina seoli kufuneka sitshintshwe, ngaphandle koko ukusetyenziswa kweoli kuya kwanda kwaye umngcipheko wokungcoliswa kwayo uya kwanda, okwandisa ngokubanzi ukugqithiswa kweengxenye zeyunithi.Kwakhona, izitywina zeoyile kufuneka zitshintshwe ekuphuhliseni ubutyebi - ixesha lokutshintsha lidla ngokuboniswa ngumenzi weyunithi.

Kuphela ezo ntlobo kunye neemodeli zeoli ye-oyile efakwe ngaphambili kwaye yacetyiswa ngumvelisi wendlela (echazwe yinxalenye yenombolo kwikhathalogu yokuqala) kufuneka isetyenziswe ukutshintshwa.Kwezinye iimeko, kuvumelekile ukuba kusetyenziswe ukutshintshwa, kodwa oku kufuneka kwenziwe ngokuqaphela kwaye kuthathelwe ingqalelo izinto ezikhethekileyo ze-cuffs ngeenjongo ezahlukeneyo.Ngokomzekelo, izitywina ze-semi-axles ze-axles ze-drive kufuneka zibe ne-notch eguqulwayo (i-knurling), kungenjalo kungekudala emva kokufakwa kwazo kuya kubakho ukuvuza kweoli kwiindlela ezithile zokuqhuba okanye ukuvuza rhoqo ngenxa yokusebenza ngokungafanelekanga kwesitywina.Ngakolunye uhlangothi, akukho ngqiqo ukubeka i-cuff ebuyela umva kwi-fan, ekubeni i-shaft etywiniweyo ihlala ijikeleza kwicala elinye.

Ukutshintshwa kwee-drive seals kufuneka kwenziwe ngokuhambelana nemiyalelo yokulungiswa nokugcinwa kwesithuthi.Lo msebenzi unokufuna i-disassembly ebalulekileyo yeyunithi elungisiweyo, ngoko kungcono ukuyithemba kwiingcali.Xa utshintshela isitywina ngokwakho, kuyimfuneko ukunamathela ngokuthe ngqo kwiingcebiso ezinikwe kwimiyalelo, ngaphandle koko kukho umngcipheko omkhulu wokonakalisa inxalenye okanye ukuyifaka ngokungalunganga.Ukuqatshelwa kwe-cuff endala kunokwenziwa nge-screwdriver eqhelekileyo okanye enye into ekhonjiweyo, kodwa oku kufuneka kwenziwe ngononophelo ukuze kungonakalisi indawo yecala kunye ne-shaft.Ukufakwa kwetywina elitsha kungcono ukwenza ngoncedo lwe-mandrel ekhethekileyo eqinisekisa ukutshona okufanayo kwetywina leoli kwibhokisi yokutywina yeoli.Ngaphambi kokufakwa, i-cuff ifakwe i-lubricant.Kwiimeko apho isitywina esinesakhelo sokuqinisa esingenanto okanye esicacileyo sisetyenzisiweyo, kuyimfuneko ukuphatha indawo yokudibanisa isakhelo kunye nomzimba weyunithi kunye ne-sealant.Emva kokwenza umsebenzi, kuyimfuneko yokongeza ioli kwi-crankcase yeyunithi.

Ngokukhetha okuchanekileyo kunye nokutshintshwa kwetywina lokuqhuba, iyunithi iya kwenza imisebenzi yayo ngokuthembekileyo, umsebenzi wayo awuyi kuphazamiseka ngokuvuza kunye nokungcoliswa kweoli kuyo nayiphi na imeko yokusebenza.

Ixesha lokuposa: May-06-2023