Enye yezona ndawo ziphambili zokusabalalisa i-ignition plate yi-plate yesiseko, ejongene nokusebenza kwe-breaker.Yonke into malunga neeplate eziqhekezayo, iintlobo zazo ezikhoyo kunye neempawu zoyilo, kunye nokukhetha, ukutshintshwa kunye nokulungelelaniswa kwezi nxalenye zichazwe ngokubanzi kweli nqaku.

Yintoni ipleyiti yokusabalalisa umlilo

Ipleyiti yokusabalalisa umlilo (i-plate yesiseko se-breaker) yinxalenye ye-ignition breaker-distributor (umthengisi);Ipleyiti yensimbi esebenza njengenkxaso yeqela loqhagamshelwano le-breaker okanye i-stator distributor ye-contactless ignition system.

Kwi-carburetor kunye ne-injini yepetroli ye-injection, inkqubo yokutshisa yakhiwe ngesiseko sesixhobo somatshini-i-breaker-distributor, edla ngokubizwa ngokuba ngumsasazi.Le yunithi idibanisa izixhobo ezimbini: i-breaker eyenza uchungechunge lwee-pulses zangoku ezifutshane, kunye nomthengisi oqinisekisa ukunikezelwa kwangethuba kwezi zixhobo kwiisilinda ze-injini (yenza imisebenzi yokutshintsha).Iinkqubo ezahlukeneyo zinoxanduva lokuqulunqa ii-pulses eziphezulu zombane kubahambisi:

● Kwinkqubo yokutshisa i-contact - i-breaker eyakhelwe kwiqela loqhagamshelwano, elivulwa ngezikhathi ezithile ngekhamera ejikelezayo;

● Kwinkqubo yokutshisa i-contactless, i-sensor (Iholo, i-inductive okanye i-optical) eyenza iimpawu zokulawula ukutshintshwa, oku, emva koko, ivelise i-high-voltage pulses kwi-coil ignition.

Zombini iinkqubo - zombini i-breaker contact yesiqhelo kunye ne-sensor - zibekwe ngokuthe ngqo kwizindlu zokusabalalisa umbane, zixhunyiwe ngomatshini kwi-rotor yokusabalalisa.Kuzo zombini iimeko, ukuxhaswa kwezi nkqubo yinxalenye ekhethekileyo - i-plate ye-breaker (okanye i-plate distributor plate).Le nxalenye idlala indima ebalulekileyo ekusebenzeni komthengisi wonke, ukungaphumeleli kwayo ngokuqhelekileyo kuphazamisa ukusebenza kwenkqubo yokutshisa.I-plate ephosakeleyo kufuneka ilungiswe okanye ithathelwe indawo, kodwa ukwenzela ukulungisa okufanelekileyo, kuyimfuneko ukuqonda iintlobo ezikhoyo zamacwecwe aqhekezayo, ukuyila kwazo kunye neempawu.

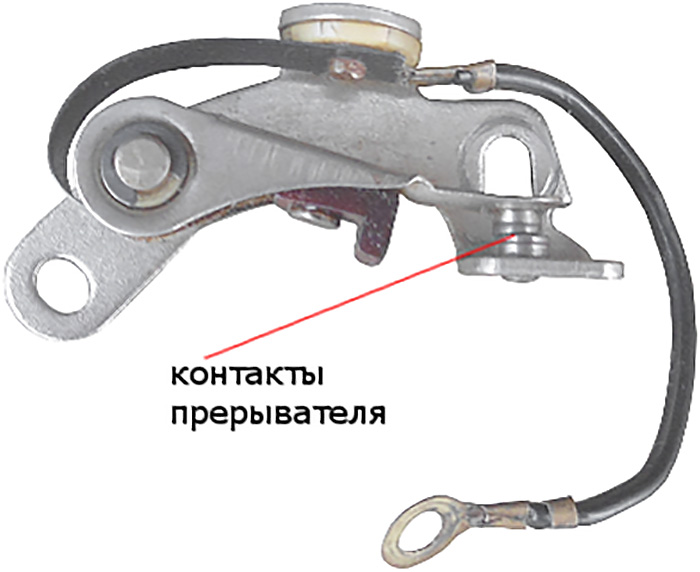

Iqela loqhagamshelwano lomqhekezi

Iintlobo, uyilo kunye nomgaqo wokusebenza kwepleyiti yokusabalalisa umlilo

Iipleyiti eziqhekezayo zohlulwe zibe ngamaqela amabini ngokohlobo losasazo lomlilo:

● Kumthengisi woqhagamshelwano;

● Kumthengisi ongaqhagamshelwanga.

Amalungu anomahluko omkhulu omnye komnye kuyilo kunye nokusebenza.

Iipleyiti eziqhekezayo zenkqubo yokudibanisa yoqhagamshelwano

Kukho iindidi ezimbini zeepleyiti zesiseko se-distributor breaker yenkqubo yokutshisa uqhagamshelwano:

● Iipleyiti ezingenazo ikheji;

● Iipleyiti ezihambelana nekheji yokuthwala.

Uyilo lomthengisi kunye neplate yesiseko esahlukileyo kunye nabafowunelwa

Uyilo olulula kakhulu ngamacwecwe odidi lokuqala.Isiseko soyilo sisitampu sentsimbi yesimo esiyinkimbinkimbi, embindini apho umngxuma ojikelezayo wenziwa kunye nekhola yokufakela ukuthwala.Ipleyiti ine threaded kunye nemingxunya elula yokunyuka iqela loqhagamshelwano kunye nokuma kunye nomtya ovakalelwayo wokuthambisa kunye nokucoca i-shaft, kunye nomngxuma owenziwe nge-wedge kwindawo yofakelo yeqela loqhagamshelwano lokulungelelanisa isithuba phakathi kwabafowunelwa bayo.Iiplati zibonelelwa nge-bearing efakwe kwi-collar kunye ne-mass wire kunye ne-terminal yohlobo oluthile okanye olunye.Iipleyiti zolu hlobo zazisetyenziswa ngokubanzi kwiimoto ezifakwe kwi-VAZ "Classic" kunye nabanye, kwiiyunithi ezinjalo, le nxalenye ibizwa ngokuba "yi-movable breaker plate".

Uyilo olunzima ngakumbi lunamacwecwe amaqhekeza odidi lwesibini.Ngokwesakhiwo, le nxalenye iqulathe izinto ezimbini: ipleyiti eshukumayo yebreaker kunye ne-bearing cage.Ipleyiti eshukumayo inoyilo olufana nolo luchazwe ngasentla, phantsi kwayo kukho i-cage yokuthwala - kunye nenxalenye yentsimbi egxininisiweyo, emacaleni apho imilenze iqulunqwa ngemingxuma yokunyuka kwizindlu zokusabalalisa.I-bearing ibekwe phakathi kweplate ehambayo kunye ne-cage, iqela loqhagamshelwano elinocingo kunye nentambo eveziweyo ifakwe kwiplate ehambayo, kwaye i-wire mass ixhunyiwe kwi-cage.

Zombini iintlobo zeepleyiti zixhonywe emazantsi ezindlu zokusasaza umlilo.I-plate ngaphandle kwe-cage yokuthwala ifakwe ngokuthe ngqo kwindlu, esebenza njenge-cage.Uhlobo lwesibini lwepleyiti lugxininiswe kwindlu enezikhonkwane ezifakwe kwi-cage yokuthwala.Iipleyiti ezihambayo ziqhagamshelwe kwi-vacuum corrector ngokusebenzisa i-traction, ngaloo ndlela itshintsha ixesha lokutshisa ngokuxhomekeke kwindlela yokusebenza kwe-injini.

Qhagamshelana nepleyiti yomthengisi we-igition

Iipleyiti zokusasaza kwinkqubo yokuvutha koqhagamshelwano zisebenza ngolu hlobo lulandelayo.Ipleyiti iqinisekisa indawo echanekileyo yeqela loqhagamshelwano ngokumalunga ne-shaft yokusabalalisa.Xa i-shaft ijikeleza, iikhamera zayo zibethe umnxibelelwano ohambayo, zibonelela ngokuphazamiseka kwexesha elifutshane lexesha langoku, ngenxa yokuba i-pulses ephezulu ye-voltage yenziwe kwi-coil yokuvutha, enikezelwa kumthengisi kwaye emva koko kumakhandlela kwiisilinda. .Xa utshintsha indlela yokusebenza ye-injini, i-vacuum corrector ijikeleza ipleyiti eshukumayo kwi-angle ethile kwicala elinye okanye kwelinye, elifezekisa utshintsho kwixesha lokutshisa.Ukujikeleza okugudileyo kwepleyiti ngelixa kugcinwa ukuqina okwaneleyo kwesakhiwo kunikezelwa ngokuthwala.

Iipleyiti zabasasazi abangenakuqhagamshelwa

Kukho iintlobo ezintathu eziphambili zeepleyiti zokusasaza ngaphandle koqhagamshelwano:

● NgeHolo yoluvo;

● Ngenzwa ye-inductive;

● Ngenzwa yokukhanya.

Kuzo zonke iimeko, isiseko senxalenye yiplate yensimbi enesitampu apho inzwa okanye esinye isixhobo sifakwe.Ipleyiti ixhonywe ngokuthwala kwizindlu zokusabalalisa kwaye idibaniswe kwi-vacuum corrector ngentonga, kunye nabaqhubi nabo babekwe kwi-plate ukuhambisa iimpawu zokulawula ezenziweyo kwi-switch.

Ipleyiti yokusabalalisa i-igition yohlobo loqhagamshelwano

Ngokuxhomekeke kuhlobo lomthengisi, iindawo ezahlukeneyo zinokubekwa kwipleyiti:

● Inzwa yeHolo - isixhobo esine-Hall chip, apho i-groove yenzelwe i-rotor exhunywe kwi-shaft yokusabalalisa;

● I-coil ye-multi-turn i-coil ejikelezayo esisiseko se-sensor yohlobo lwe-inductive, i-magnet edibeneyo kwi-rotor yokusabalalisa isebenza njenge-rotor kwi-sensor enjalo;

● I-sensor optical sisixhobo esine-LED kunye ne-photodiode (okanye i-photoresistor), ehlulwe yi-groove ye-rotor ene-cutouts exhunywe kwi-shaft yokusabalalisa.

Eyona nto isetyenziswa kakhulu i-sensor-distributors ezakhiwe ngesiseko se-sensor yeHolo - zinokufumaneka kwiimoto zeVAZ kunye neelori ezininzi.Abenzi boluvo inductive zisetyenziswa kakhulu ngaphantsi rhoqo, abasasazi ezinjalo zifumaneka kwiimoto GAZ-24 kunye kamva Volga, iimodeli UAZ ngabanye kunye nabanye.Iinzwa ze-Optical-distributors kwiimoto zasekhaya azisetyenziswanga, zinokubonwa kwezinye iimoto ezenziwe kwamanye amazwe ezineenjini ze-carburetor.

Indlela yokukhetha kunye nokubuyisela ipleyiti yokusabalalisa umlilo

Ngethuba lokusebenza komthengisi, i-plate ye-breaker ixhomekeke kwimithwalo yomatshini kunye ne-thermal, ekhokelela ekugqokeni ngokuthe ngcembe kwamalungu ayo (ngokuyinhloko iqela loqhagamshelwano), ukuguqulwa kunye nomonakalo.Konke oku kubonakaliswa ukuwohloka kwenkqubo yokutshisa, kubandakanywa utshintsho oluzenzekelayo kwixesha lokutshisa okanye ukungakwazi ukuyilungisa, ukubonakala kokuphazamiseka ekusebenzeni kweesilinda ngabanye, ukuwohloka kokuqala, njl.

Ukutshintshwa, kufuneka uthathe ipleyiti ye-breaker kuphela yohlobo (inombolo yekhathalogu) efakwe kwi-distributor ngaphambili, okanye inconywa ngumenzi wokusabalalisa.Ukufakela ipleyiti entsha, kuyimfuneko ukuqhawula kunye nokuqhaqha umhambisi (ekubeni le nxalenye ibekwe ezantsi kweyunithi, kufuneka ususe umthengisi kunye nomlawuli ukufikelela kuyo) - oku kufuneka kwenziwe ngokuhambelana nemiyalelo. ukulungisa injini okanye imoto ethile.Ipleyiti entsha kufuneka iwele endaweni ngaphandle komzamo kwaye ijikeleze ngokukhululekileyo ekuthwaleni.Ngethuba lokufakela, ingqalelo kufuneka ihlawulwe ekudibaneni kweplate kunye ne-vacuum corrector kunye nazo zonke ii-terminals zombane.

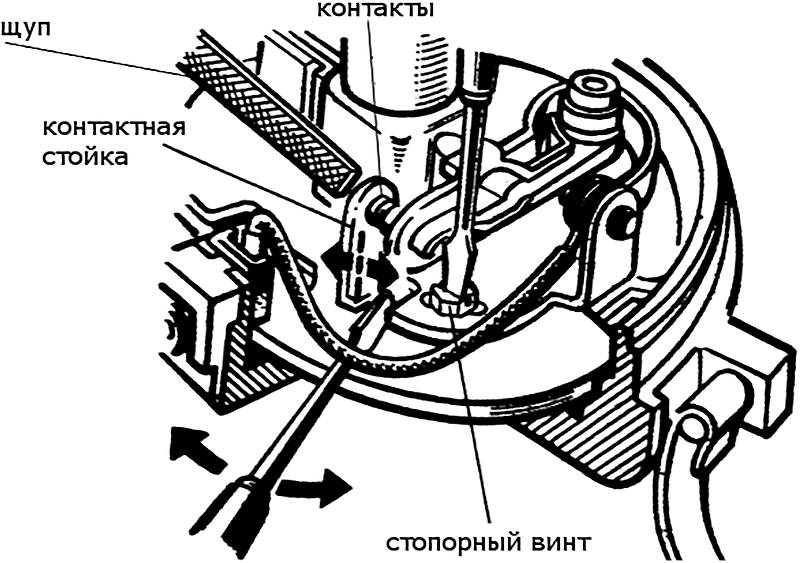

Ukulungelelaniswa kweqela loqhagamshelwano labahambisi

Ngethuba lokusebenza komthengisi, iingxaki zingabonakala zingahambelani nemeko yeplate, kodwa zibangelwa utshintsho kwisithuba phakathi kwabafowunelwa beqhekeza.Ukucombulula le ngxaki, kufuneka udibanise ngokuyinxenye umthengisi ngokususa isigqubuthelo, kwaye ulinganise umsantsa phakathi kwabafowunelwa - kufuneka ulale ngaphakathi kwimida ebekwe ngumenzi walo msasazi.Ukuba i-gap ihluke kwi-efakwe, ngoko kuyimfuneko ukukhulula i-screw edibanisa iqela lokudibanisa kwi-plate kwaye ulungise i-gap, uze uqinise i-screw.Kwakhona kunokuba yimfuneko ukucoca abafowunelwa kwi-soot nge-sandpaper.

Ngokukhetha okuchanekileyo kunye nokutshintshwa kwepleyiti ye-breaker-distributor okanye i-sensor yokusabalalisa, inkqubo yokutshisa iya kusebenza ngokuzithemba nangokuthembeka kuzo zonke iindlela zokusebenza ze-injini.

Ixesha lokuposa: Jul-10-2023