Kwiinguqu zangoku zeenjini ze-KAMAZ, inkqubo yokupholisa ioli inikezelwa, eyakhelwe kwiyunithi enye - i-oil heat exchanger.Funda konke malunga nala macandelo, iintlobo zazo, ukuyila, umgaqo wokusebenza kunye nokusebenziseka, kunye nokukhetha okufanelekileyo, ukulungiswa kunye nokutshintshwa kokutshintshwa kobushushu kweli nqaku.

Yintoni i-KAMAZ yokutshintsha ubushushu beoli?

Umtshintshi wobushushu be-oyile (i-liquid-oil heat exchanger, LMT) yinxalenye yeenkqubo zokuthambisa kunye nokupholisa kwiiyunithi zamandla aphezulu edizili;Isitshintshi sobushushu esiyilwe ngokukodwa esakhelwe kwisixokelelwano sokupholisa solwelo lwe-injini, esibonelela ngokupholisa kwe-oyile ye-injini ngenxa yokutshintshiselana kobushushu kunye nokuhamba kwesipholisi.

Inkqubo yokuthambisa yeeyunithi ze-diesel ze-KAMAZ ezinamandla zisebenza kwiimeko ezinzima, ioli ihlala ibonakaliswe kumaqondo okushisa aphezulu kwaye ngokuthe ngcembe ilahlekelwa yimpawu zayo.Kwezinye iindlela, i-oyile ye-injini inokutshisa kakhulu, nto leyo ekhokelela ekunciphiseni i-viscosity kunye nokuthambisa, kunye nokubola okukhulu kunye nokudinwa.Ekugqibeleni, i-oyile eshushu kakhulu iyonakalisa ukusebenza kwe-injini kwaye inokubangela ukuba isilele.Le ngxaki ixazululwa ngokuzisa into yokupholisa ioli - i-heat exchanger - kwinkqubo ye-lubrication yeenjini ze-KAMAZ.

I-oyile yokutshintshiselana kobushushu yinxalenye ebalulekileyo ye-injini yokuthambisa kunye neenkqubo zokupholisa, iqinisekisa ukususwa kobushushu obugqithisileyo kwi-oyile ngenxa yokutshintshiselana kobushushu obusebenzayo kunye nokuhamba kwewasha yokupholisa (epholileyo).Yiyo loo nto izixhobo zolu hlobo zibizwa ngokuba zii-liquid-oil exchange exchangers, okanye i-LMT.Le yunithi yenza imisebenzi emininzi:

- Ukupholisa inxalenye yeoli kwiqondo lobushushu le-injini elingaphantsi kwe-100 degrees;

- Ukupholisa kwayo yonke ioyile ingena kwi-injini kwiqondo lobushushu kwiqondo le-100-110 degrees;

- Ukunciphisa ukusetyenziswa kweoli kwinkcitho kunye nokwandisa ubomi bayo;

- Ukuqinisekisa olona lawulo lobushushu lweenkqubo ezahlukeneyo ze-injini - ngenxa ye-LMT, iqondo lobushushu le-oyile alize lehle ngaphantsi kweqondo lokupholisa, nto leyo enegalelo ekufudumezweni okufanayo kwamalungu e-injini, ukuncipha koxinzelelo lomatshini, njl.njl.;

- Ukwenza lula uyilo lwenkqubo yokupholisa i-oyile kunye nokunciphisa iindleko ze-injini ngelixa uqinisekisa iimpawu eziqhelekileyo zokusebenza kwayo.

Namhlanje, abatshintshi bokushisa bafakwe kwiinjini ezininzi ze-diesel ze-KAMAZ ezihlangabezana nemigangatho ye-Euro-2 nangaphezulu, badlala indima ebalulekileyo ekuqinisekiseni iimpawu eziqhelekileyo zeyunithi yamandla kuzo zonke iindlela zokusebenza.Umtshintshi wokushisa ophosakeleyo kufuneka ulungiswe okanye utshintshwe ngokupheleleyo ngokukhawuleza, kodwa ngaphambi kokuthenga inxalenye entsha, kufuneka uqonde ukuyila kunye nokusebenza kwezi zixhobo.

Uyilo kunye nomgaqo wokusebenza kwe-KAMAZ yeoli yokutshintshiselana kobushushu

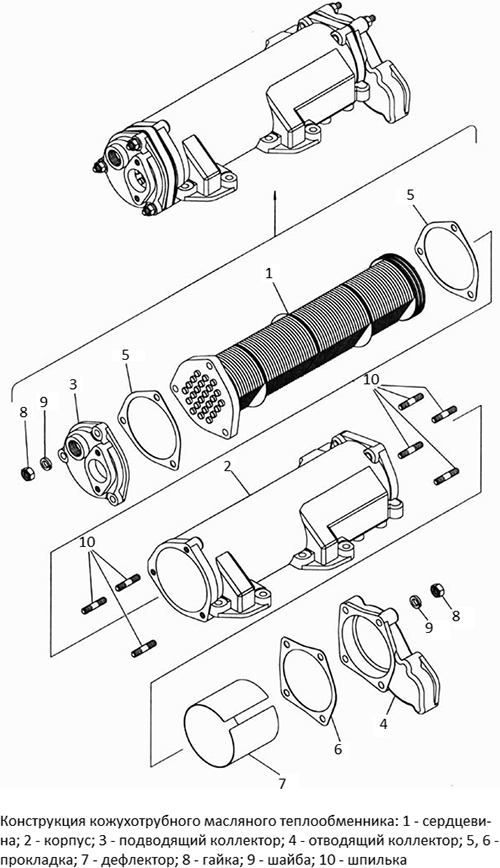

Kwiinjini ze-KAMAZ, kuphela uhlobo lweqokobhe kunye netyhubhu (i-tubular) uhlobo lweqokobhe kunye netyhubhu (i-tubular) uhlobo lohlengahlengiso olwahlukeneyo olusetyenziswayo okwangoku.Ngokwesakhiwo, le yunithi ilula kakhulu, iqulathe la macandelo alandelayo:

● Umzimba (i-casing);

● Undoqo ngesiphambuli;

● Ukungenisa ngokuphindaphindiweyo;

● Ukukhupha ngokuphindaphindiweyo.

Isiseko soyilo ngumzimba we-aluminium cylindrical (i-casing), eludongeni apho iziteshi kunye neendawo zokuzalisa zenziwe ukudibanisa kwibhloko yokucoca ioli (ufakelo lwenziwa ngee-gaskets).Iziphelo ze-casing zivaliwe ngamagquma akhethekileyo anemibhobho - i-inlet kunye ne-outlet manifolds, eyokuqala ibonelela ngokupholisa kwibhatyi yamanzi yebhloko ye-cylinder ngaphakathi kwendlu, kwaye okwesibini iguqula ulwelo emva kwenkqubo yokupholisa injini.Ukugrunjwa kunye nemijelo kuyenziwa kumzimba wokufakelwa kweevalve ze-bypass, eziqinisekisa ukuba i-oyile idlula ngokudlula umtshintshi wokushisa xa i-core yayo ivaliwe.

I-core ifakwe ngaphakathi kwecala - indibano yobhedu olubhityileyo okanye iityhubhu zobhedu ezibekwe kwipakethe yeepleyiti zetsimbi ezinqamlezileyo.Kwisiseko kukho iiplati ezintlanu ezinenxalenye ephumayo, eyahlula yonke inxalenye ibe ngamacandelo amane, enika utshintsho kwindlela yokuhamba kweoli.Kwelinye icala londoqo kukho i-flange, ethi, ngexesha lofakelo, iphumle ekupheleni komzimba, kwelinye icala i-flange inobubanzi obufana nokungena ngokuqinileyo kwi-casing, kwaye kukho i-O-rings ezininzi. yona.Olu luyilo luqinisekisa ukuhlukana kokuhamba kokupholisa kunye neoli, ukuthintela ukuxubana.Kwaye ulwalathiso oluchanekileyo lokuhamba kweoli, i-deflector ibekwe kwelinye icala le-core - intsimbi evulekileyo yentsimbi ene-slot.

Uyilo lwe-KAMAZ yokutshintsha ubushushu beoli

Kwi-LMT edibeneyo, umtshintshi wokushisa kunye neenqwelo-moya ezimbini ezizimeleyo zenziwa: i-coolant ihamba ngeetyhubhu eziphambili, kwaye ioli ihamba ngesithuba phakathi kweetyhubhu kunye neendonga ze-casing.Ngenxa yokwahlulwa kwengundoqo kumacandelo amane, indlela yokuhamba kweoli iyanda, efezekisa ukuhanjiswa kokushisa okusebenzayo kwe-coolant.

I-LMT ifakwe kwi-injini ye-injini kunye nebhloko yesihluzo se-oyile (ivalve ye-thermopower elawula ukuhamba kwe-oyile ngokutshintshiselana kobushushu ikwakhona apha), unikezelo lwayo kunye ne-outlet manifolds idityaniswe kwimibhobho ehambelanayo kwibhloko yesilinda.Kwiindlela ezininzi zokuyila, i-manifold yokubonelela idibaniswe kwibhloko ngokusebenzisa umbhobho omfutshane, kwaye i-dischage manifold ixhunywe ngokusebenzisa indawo yokuzalisa.

I-LMT isebenza ngolu hlobo lulandelayo.Xa ubushushu be-injini bungaphantsi kwama-95 degrees, i-valve yamandla e-thermal ivaliwe, ngoko yonke i-oyile ehamba ngepompo ye-oyile idlula kwiifilitha kwaye ingena ngokukhawuleza kwi-injini yokuthambisa.Xa iqondo lokushisa liphakama ngaphezu kwama-95 degrees, ivalve ivula, kwaye inxalenye yeoli evela kwizihluzi ithunyelwa kwi-LMT - apha idlula ngaphakathi kwe-casing ejikeleze umbindi, ikhupha ubushushu obugqithisileyo kwisipholisi esidlula kwimibhobho, kwaye kuphela. emva koko ingene kwinkqubo yokuthambisa injini.Xa iqondo lokushisa liphakama ngaphezu kweedigri ze-100, i-valve ye-thermal iqondisa yonke ukuhamba kweoli ukusuka kwiifilitha ukuya kwi-LMT.Ukuba ngenxa yaso nasiphi na isizathu ubushushu be-injini bugqithile kwi-115 degrees, ukupholisa kwe-oyile kwi-LMT kungasebenzi kwaye ukufudumeza okugqithisileyo kunokwenzeka - isalathisi esihambelanayo kwideshbhodi silumkisa ngokuqalisa kwemeko kaxakeka.

Ukusetyenziswa kwe-oyile yokutshintshiselana kobushushu kwiimoto ze-KAMAZ

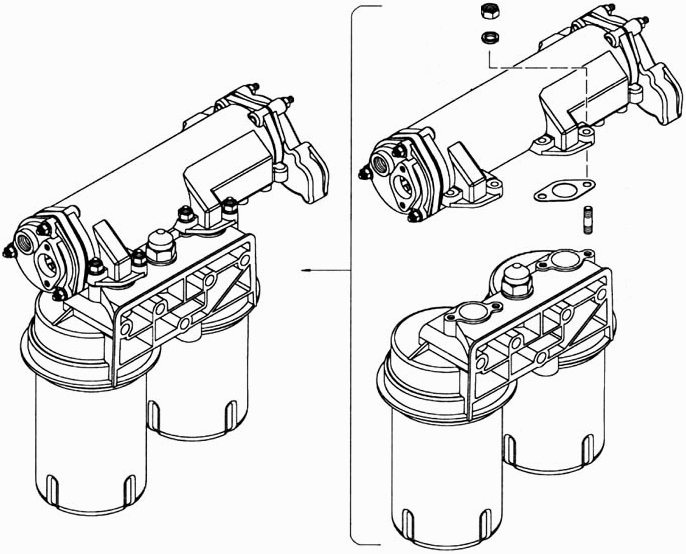

Ii-LMT zifakwe kuphela kwi-KAMAZ 740 yeenjini zedizili zohlengahlengiso ezahlukeneyo ze-Euro-2, 3 kunye ne-4 iiklasi zokusingqongileyo.Zimbini iintlobo zokutshintsha ubushushu ezisetyenziswayo namhlanje:

● Inombolo yekhathalogu 740.11-1013200 - ukuguqulwa okufutshane;

● Inombolo yekhathalogu 740.20-1013200 luhlengahlengiso olude.

Umahluko phakathi kwezi nxalenye ulele ekuyilweni kwabaqokeleli kwaye, ngenxa yoko, kwindlela yokudibanisa kwinkqubo yokupholisa.Kwi-LMT emfutshane, i-manifold yokukhupha inomhlaba wokuzalisa kuphela ekupheleni kokudibanisa umbhobho usebenzisa iibholithi okanye izikhonkwane.Abatshintshi bobushushu abane-manifold enjalo bakwindawo yonke, bafanelekile kwiinjini ezininzi ze-KAMAZ zeeklasi ezahlukeneyo zokusingqongileyo.Kwi-LMT ende kwi-outlet manifold kukho umbhobho wokudibanisa i-hose kunye nentsimbi yentsimbi.Kungenjalo, omabini la malungu ayafana kwaye anokudityaniswa kwiindibano zokucoca eziqhelekileyo.

Ukufakwa kwe-Oli ye-KAMAZ yokutshintshisa ukushisa kweoli kwiyunithi yokucoca ioli

Kwakhona, kwiindawo ze-heat exchanger, ngenxa yeenkqubo zokubola okanye umonakalo, ukuqhekeka kunye nokuqhekeka kwenzeka apho ioli ingena kwi-coolant.Ingxaki efanayo ibonwa xa izinto zokutywina zigugile okanye zonakaliswe.Kule meko, i-LMT kufuneka ilungiswe okanye itshintshwe ngokupheleleyo.Namhlanje, kukho izixhobo ezahlukeneyo zokulungisa kwimarike equkethe i-gaskets, ii-cores, ii-manifolds kunye nezinye iindawo.Ukuba ukulungiswa akunakwenzeka okanye akunakwenzeka, ngoko kuyimfuneko ukutshintsha ngokupheleleyo inxalenye.Wonke umsebenzi wenziwa ngokuhambelana nemiyalelo yokulungiswa nokugcinwa kwesithuthi.Ngaphambi kokulungiswa, i-coolant kunye nenxalenye yeoli iyachithwa, emva kokutshintshwa, zonke ii-fluids ziziswa kwinqanaba elifunekayo.Emva koko, i-LMT ifuna kuphela ukuhlolwa rhoqo kunye nokuqinisekiswa kweevalvu ngexesha lokugcinwa kwesiqhelo.

Ukuba umtshintshi wobushushu ukhethiwe kwaye ufakwe ngokuchanekileyo, ke i-oyile ye-injini iya kuhlala ineqondo lobushushu elifanelekileyo, iqinisekisa ukusebenza kakuhle kweyunithi yamandla.

Ixesha lokuposa: Jul-13-2023