Kuyo nayiphi na i-piston injini yokutsha yangaphakathi kukho inxalenye edibanisa i-piston kwintloko ephezulu yentonga yokudibanisa - ipiston yepiston.Yonke into malunga nezikhonkwane zepiston, iimpawu zabo zokuyila kunye neendlela zokufakela, kunye nokukhetha okuchanekileyo kunye nokutshintshwa kweentlobo ezahlukeneyo zezikhonkwane zichazwe ngokucacileyo kwinqaku.

Yintoni ipiston pin

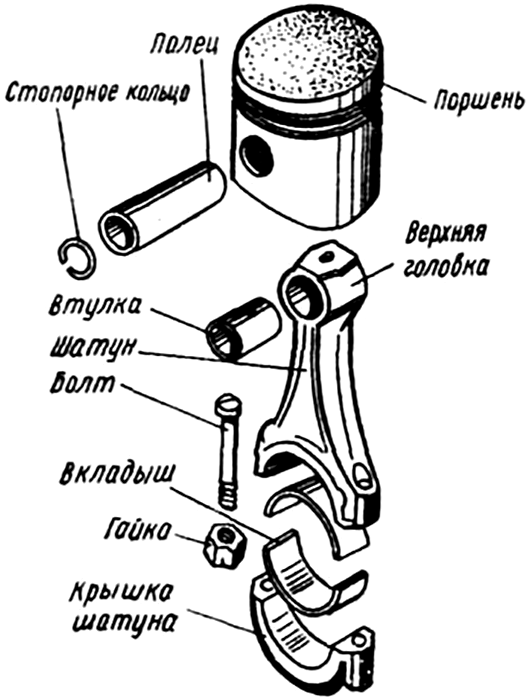

Ipiston yepiston (PP) yinxalenye yeqela lepiston yenjini yokutsha yangaphakathi;i-cylinder yentsimbi engenanto, ngoncedo apho i-piston kunye nentonga yokudibanisa ixhomekeke.

Ekubuyiseleni iinjini zokutsha zangaphakathi, ukuhanjiswa kunye nokuguqulwa kwemikhosi evela ekutshisweni komxube we-fuel-air kwi-cylinder iqhutyelwa liqela lepiston kunye ne-crank mechanism.Iindawo eziphambili zezi nkqubo ziquka ipiston kunye nentonga yokudibanisa kunye ne-hinge joint, ngenxa yokuba kunokwenzeka ukuphambuka i-axis yentonga yokudibanisa kwi-piston axis xa iphakathi kwamaziko aphezulu nangaphantsi afile (TDC kunye ne-TDC).Ukudibanisa i-hinge ye-piston kunye nentonga yokudibanisa iphunyezwa ngokusebenzisa inxalenye elula - ipiston yepiston.

Iphini yepiston isombulula imisebenzi emibini ebalulekileyo:

● Isebenza njengehenjisi phakathi kwepiston kunye nentonga yokudibanisa;

● Ukubonelela ngokutshintshela amandla kunye neetorque ukusuka kwintonga yokudibanisa ukuya kwipiston xa uqalisa injini kunye nokusuka kwipiston ukuya kwintonga yokudibanisa xa injini isebenza.

Oko kukuthi, i-PP ayidibanisi ipiston kuphela kunye nentonga yokudibanisa kwisistim enye (ekwabandakanya i-crankshaft), kodwa ngokubanzi iqinisekisa ukusebenza okuhambelanayo kweqela lepiston kunye ne-injini ye-crank mechanism.Ke ngoko, nakuphi na ukungasebenzi kakuhle okanye ukunxiba komnwe kuchaphazela kakubi ukusebenza kweyunithi yonke yamandla, efuna ukulungiswa ngokukhawuleza.Kodwa ngaphambi kokuthenga izikhonkwane ezintsha zepiston, kufuneka uqonde ukuyila kwazo kunye nezinye izinto.

Iintlobo, isixhobo kunye neempawu zepiston izikhonkwane

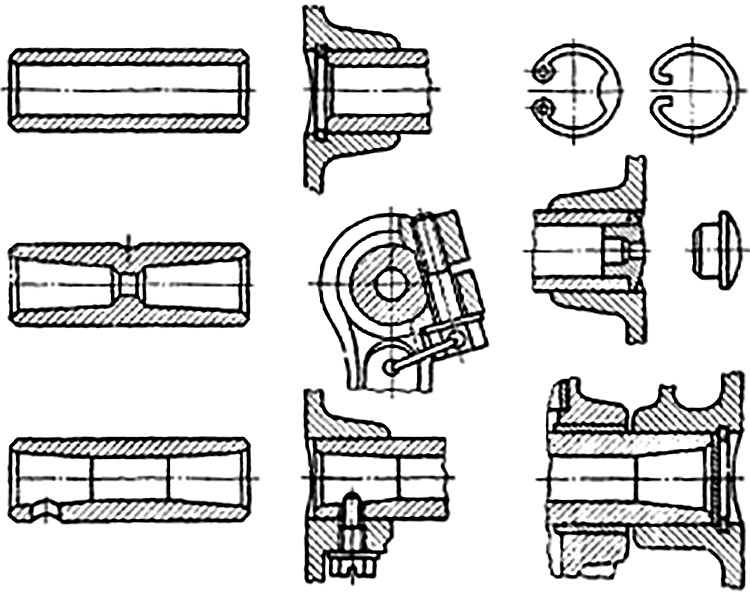

Zonke izikhonkwane zepiston ezisetyenziswayo ngoku zinoyilo olufanayo: ngokubanzi, yintonga yentsimbi engenanto eneendonga ezicekethekileyo ezifakwe kubaphathi bepiston kunye nentloko yentonga yokudibanisa ephezulu.Ekupheleni kwepini, ii-chamfers (zangaphandle nangaphakathi) ziyasuswa, eziqinisekisa ukufakwa lula kwenxalenye kwipiston okanye intonga yokudibanisa, kunye nokuthintela umonakalo kwezinye iindawo xa udibana nabo ngengozi.

Kwangaxeshanye, izinto ezahlukeneyo ezincedisayo zinokwenziwa kwiminwe:

● Ukuzisa iindonga zangaphakathi kwikhoni ukusuka embindini ukuya ngaphandle ukuze ukhanyise umnwe ngelixa ugcina amandla ayo;

● Iibhanti zendandatho zangaphakathi kwindawo ephakathi komnwe ukuyiqinisa;

● Imingxuma enqamlezileyo esecaleni yokulungiswa okuqinileyo kwephini kumphathi wepiston.

Izikhonkwane zepiston zenziwe ngekhabhoni ethambileyo yesakhiwo (i-15, i-20, i-45 kunye nezinye) kunye nezinye i-alloyed (ngokuqhelekileyo i-chromium 20X, 40X, 45X, 20HNZA kunye nezinye) iintsimbi.Umphandle wangaphandle kunye nebhanti encinci ekupheleni kweengxenye ezenziwe ngeentsimbi ezithambileyo zifakwe kwi-carburized kwaye zicinywe ukuya kubunzulu be-1.5 mm de kube bunzima be-55-62 HRC bufikeleleke (ngelixa umaleko wangaphakathi unobunzima kuluhlu lwe-22- 30 HRC).Iingxenye ezenziwe ngeentsimbi zekhabhoni eziphakathi zihlala ziqiniswe kunye nemisinga ephezulu ye-frequency currents.Emva kokunyanga kobushushu, indawo yangaphandle yePP iphantsi kokugaya.Ukuqina kwenxalenye kubonelela ukuchasana okuphezulu kwendawo yayo yangaphandle ukuba inxibe, ngelixa i-viscosity yemigangatho yangaphakathi eludongeni igcina ukukwazi komnwe ukujamelana nemithwalo yokuthuthumela kunye nokungcangcazela.Ukugaya umphezulu kuphelisa iindawo ezinoxinzelelo oluyingozi, oluthi ngexesha lokusebenza kwe-injini lukhokelela ekukhutsheni, ukuqina okanye ukutshatyalaliswa kwamalungu.

Uyilo lwepiston oluqhelekileyo kunye nentonga yokudibanisa

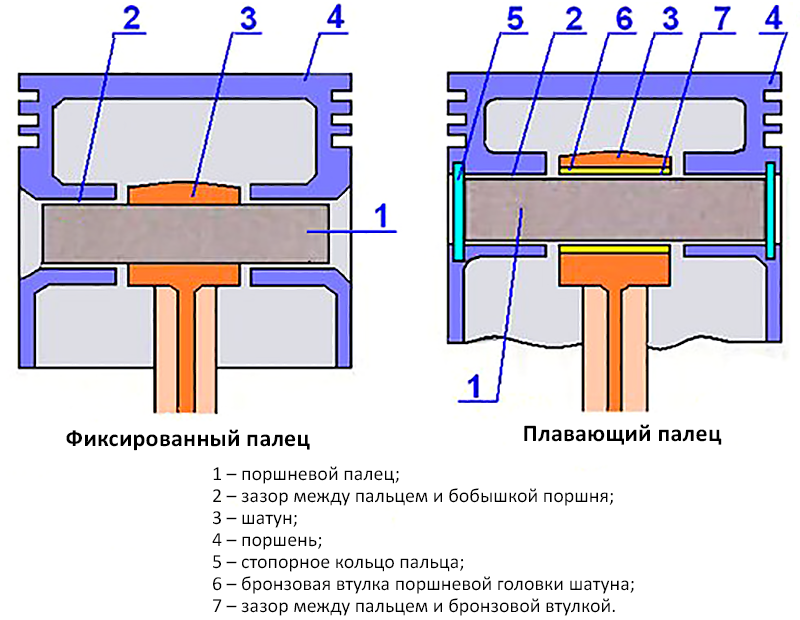

Njengoko sele kubonisiwe, i-piston pin ifumaneka kwi-piston kunye nentloko ephezulu yentonga yokudibanisa, idibanisa ezi nxalenye kwinkqubo enye.Kwipiston yale nxalenye kukho izandiso ezimbini ezinemingxuma enqamlezileyo - abaphathi.Kukho iinketho ezimbini zoyilo lwehenjisi phakathi kwepiston kunye nentonga yokudibanisa:

● Ngomnwe "odadayo";

● Ngokucinezela ngomnwe kwintonga yokudibanisa.

Iskimu sesibini siphunyezwa ngokulula: kulo mzekelo, iPP icinezelwe ibe phezulu (iqhekeza elinye) intloko yentonga yokudibanisa, ethintela ukufuduka kwayo kwe-axial, kwaye kubaphathi bepiston ifumaneka ngesithuba esithile. , okwenza kube lula ukuguqula i-piston ngokumalunga nePP ngexesha lokusebenza kweyunithi yamandla kuzo zonke iindlela.Kwakhona, i-gap ibonelela nge-lubrication yeendawo zokuxubha (nangona ngenxa yesikhewu esincinci, umnwe kunye neendawo zabaphathi abanxibelelana nazo zihlala zisebenza kwimowudi yokuthambisa enganeleyo).Esi sikimu sasetyenziswa kwiimoto zasekhaya i-VAZ-2101, i-2105, i-2108, isetyenziswa ngokubanzi kwiimodeli zanamhlanje zemveliso yangaphandle.

Inkqubo yeminwe "edadayo" inzima ngakumbi, njengoko inamalungu amaninzi ancedisayo.Kulo cwangciso, i-PP ene-gap encinci ifakwe kuzo zombini iindawo - zombini kubaphathi bepiston kunye nentloko yentonga yokudibanisa, oku kuqinisekisa ukujikeleza kwayo kwamahhala ngexesha lokusebenza kweenjini.Ukuthintela ukufuduka kwe-axial yomnwe, amakhonkco okugcina ashushu asetyenzisiweyo, abekwe ngaphaya kwemingxunya kubaphathi - basebenza njengeendawo zokumisa iPP, ukukhusela ukuba ingawa.Amakhonkco angenziwa ngocingo lwasentwasahlobo kunye nesetyhula-cross-section okanye isitampu kwi-sheet metal.Kwimeko yokugqibela, iinxalenye zine-cross-section ye-rectangular, kwaye imingxuma yesixhobo inikezelwa kwiiphelo zombini ukuze kube lula ukufakela kunye nokususwa kwamakhonkco.

Kwezinye iimeko, ukutshixa i-fungi okanye iiplagi zisetyenzisiweyo, zenziwe ngetsimbi ethambileyo, ngoko azilonakalisi isibuko se-cylinder xa sidibana nayo.Iiplagi zisetyenziselwa iinjini ezimbini ze-stroke kunye nelungiselelo elithile lokungena kunye nokukhupha iifestile, ukuthintela ukuhamba kwegesi okungafunekiyo phakathi kwabo.Ngamanye amaxesha isetyenziselwa ukulungisa inxalenye nge-screw screwed kwindawo engezantsi yomphathi kunye nomngxuma ekupheleni kwePP.

Izikhonkwane zepiston ezizinzileyo nezidadayo

I-PP, kungakhathaliseki ukuba yeyiphi indlela yokufakela kwayo, inokuba ne-displacement ngokubhekiselele kwi-axis ye-piston, ifikelele kwi-millimeter enye nesiqingatha okanye ngaphezulu.Oku kufuduswa kujolise ekunciphiseni imithwalo eguquguqukayo apho i-piston, i-PP kunye nentloko yentonga yokudibanisa iphantsi kwe-TDC kunye ne-TDC.I-piston ekuhambeni kwayo ukuya kwi-TDC kunye ne-TDC icinezele udonga olulodwa lwe-cylinder, ekhokelela ekucinezeleni kwePP ngokuchasene nodonga olulodwa lwemingxuma ngaphakathi kwabaphathi.Ngenxa yoko, kukho imikhosi eyenza kube nzima ukuguqula i-PP kwiindawo zokukhwelana, kwaye xa udlula i-TDC kunye ne-TDC, ukujika kunokwenzeka ngokukhawuleza - oku kwenzeka ngokubetha, okubonakaliswa ngokungqongqoza kwempawu.Ezi zinto zipheliswe ngokuchanekileyo ngokufaka iPP kwipiston kunye nokususwa kwe-axis.

Indlela yokukhetha kunye nokutshintsha ipiston yepiston

Ngethuba lokusebenza kwe-injini, ngakumbi kwiindlela ezitshintshileyo, iminwe iphantsi kwemithwalo ebalulekileyo, igugile, inokukhubazeka kwaye ifuna ukutshintshwa.Isidingo sokutshintsha iminwe iboniswa ngokuwohloka koxinzelelo kunye nokuncipha kweempawu eziguqukayo ze-injini, ezongezelelweyo zibonakaliswa ngokungqongqoza kweempawu.

Ukulungiswa kweyunithi yamandla kule meko kuncitshiswe ekutshintshweni kweminwe, kwaye ngamanye amaxesha iinxalenye zokukhwelana - ukudibanisa i-rod head bushings kwiinkqubo ezinePP "ezidadayo", amakhonkco kunye nabanye.Ukukhethwa kweminwe emitsha kunye nezinye iindawo zenziwa ngokwemilinganiselo yokulungisa.Ngokomzekelo, kwii-injini ezininzi zasekhaya, iinxalenye zobukhulu obuthathu bokulungisa zinikezelwa, zihluke ngo-0.004 mm (umzekelo, iinjini zeVAZ zihlala zisebenzisa izikhonkwane ezinobubanzi obuyi-21.970-21.974 mm (udidi lokuqala), 21.974-21.978 mm (udidi lwesibini) kunye ne-21.978-21.982 mm (udidi lwe-3)).Oku kwenza ukuba kube lula ukukhetha izikhonkwane zobubanzi obuhlukeneyo, kuthathelwa ingqalelo ukunyuka kweemitha zemingxuma kwiindawo zokukhwelana ngenxa yokugqoka kunye nokuxhamla okulandelayo.I-Boring isoloko isenziwa kwimilinganiselo efanayo yokulungisa, kwaye ukuba ukunxiba kwamacandelo kudlula uluhlu oluchaziweyo, ngoko kufuneka lutshintshwe.

Njengomthetho, iminwe ithengiswa kwiisethi (2, 4 okanye ngaphezulu iziqwenga), ngamanye amaxesha kunye namakhonkco okugcina kunye nezinye iindawo.

Izikhonkwane zepiston zeentlobo ezahlukeneyo kunye neendlela zokulungiswa kwazo kwipiston

Xa kulungiswa iqela le-piston ngezikhonkwane "ezidadayo", akukho mfuneko yokusebenzisa izixhobo ezikhethekileyo - ukufakwa kweengxenye kubaphathi kunye nentloko yentonga yokudibanisa yenziwa ngumzamo wezandla.Ukuba umnwe utshintshiwe ngokulungiswa kwintonga yokudibanisa, ngoko kufuneka usebenzise isixhobo esikhethekileyo sokucinezela kunye nokucofa iPP (kwimeko elula, ezi zinokuba yi-bushings kunye neentonga, kodwa iingcali zisebenzisa izixhobo eziyinkimbinkimbi ezifana ne-vice. ).

Kwezinye iimeko, ukufakwa kwePP "ejikelezayo" kubaphathi kuqhutyelwa ngokuphazamiseka, kuba le piston ishushu emanzini okanye enye i-liquid ukuya kwi-55-70 ° C ngaphambi kokufakwa.Inyaniso kukuba i-aluminium piston ikhula ngokukhawuleza kunepini yentsimbi, ngoko kwi-injini engatshisiyo, i-gap phakathi kwamacandelo iyanda kwaye i-knock ibonakala.Xa ufaka i-PP ekuphazamiseni, i-gap iyenzeka kuphela xa i-motor ifudumala, ekhusela impembelelo yeengxenye kwaye, ngokufanelekileyo, ibetha.

Kufuneka kuqatshelwe ukuba umsebenzi wokutshintsha izikhonkwane zepiston ufuna ukuchithwa okubalulekileyo kwe-injini, ngoko ke kungcono ukuwenza ngamava afanelekileyo okanye iingcali zokuthembela.Kuphela ngokukhetha okufanelekileyo kweminwe kunye nokulungiswa okufanelekileyo, iqela lepiston liya kusebenza ngokuthembekileyo nangokufanelekileyo, liqinisekisa ukusebenza okuphezulu kweyunithi yamandla.

Ixesha lokuposa: Jul-11-2023