Kuyo nayiphi na injini yepiston yanamhlanje kukho iindawo eziqinisekisa ukuqina kwegumbi lokutsha kunye nokuthambisa iisilinda - amakhonkco episton.Funda konke malunga namakhonkco episton, iintlobo zazo ezikhoyo, iimpawu zoyilo kunye nokusebenza, kunye nokukhetha okuchanekileyo kunye nokutshintshwa kwamakhonkco kwinqaku elicetywayo.

Yintoni amakhonkco episton?

Amakhonkco e-piston - iinxalenye zeqela le-cylinder-piston (CPG) ye-injini yokutsha yangaphakathi;amakhonkco esinyithi anokushenxiswa afakwe kwiipiston ukuze atywine igumbi lokutsha, ukunciphisa ilahleko yeoli ye-injini kunye nokunciphisa ubungakanani begesi yokukhupha engena kwi-crankcase.

Ukusebenza okuqhelekileyo kwe-injini yokutshisa yangaphakathi yepiston, kubaluleke kakhulu ukuba uxinzelelo olugqithise kwinqanaba elithile elincinci lenziwe kwigumbi lokutshisa ekupheleni koxinzelelo loxinzelelo (xa ipiston ifikelela kwiziko eliphezulu lokufa) - le parameter ibizwa ngokuba ucinezelo.Kwiinjini zepetroli, uxinzelelo luhlala kuluhlu lwe-9-12 ye-atmospheres, kwiiyunithi ze-diesel le parameter yi-22-32 atmospheres.Ukufezekisa ukunyanzeliswa okufunekayo, kuyimfuneko ukuqinisekisa ukutywinwa kwegumbi lokutsha - le ngxaki ixazululwa ngamakhonkco episton.

Amakhonkco episton enza imisebenzi emininzi ebalulekileyo:

● Ukutywinwa kwegumbi lokutsha - ubungakanani bendandatho bukhethwe ngokuthe ngqo ngokwe-diameter yangaphakathi ye-cylinder, okuthintela ukuqhuma kweegesi ukusuka kwigumbi lokutsha ukuya kwi-crankcase;

● Ukunciphisa amandla okubetha - indawo yokuxhatshazwa kweendandatho kwiindonga ze-cylinder incinci kakhulu kunommandla wepiston, okunciphisa ukulahleka kweentsimbi ze-CPG;

● Imbuyekezo yokwandiswa kwe-thermal yezinto ze-CPG - iipistoni kunye neesilinda zenziwe ngama-alloys ahlukeneyo kunye ne-coefficients ehlukeneyo yokwandiswa kwe-thermal, ukuqaliswa kweendandatho kuthintela i-jamming ye-pistons kunye nokutshintsha koxinzelelo xa ubushushu be-injini bukhuphuka kwaye buwa;

● Ukuthanjiswa kweendonga ze-cylinder kunye nokususwa kweoli eninzi (eyithintela ukuba ingangeni kumagumbi okutsha kunye nokunciphisa ilahleko yeoli ngenxa yenkunkuma) - amakhonkco oyilo olukhethekileyo aqinisekisa ukukhutshwa kweoli engaphezulu kwiindonga ze-cylinder ezenziwe ngexesha lokusebenza kwe-injini, kodwa shiya ifilimu yeoli efunekayo ukunciphisa ukukhuhlana;

● Ukupholisa iindonga zepiston - inxalenye yobushushu obuvela kwipiston isuswe kwiindonga ze-cylinder ngokusebenzisa amakhonkco.

Kulula ukubona ukuba amakhonkco episton adlala indima ebalulekileyo ekusebenzeni kweCPG kunye nokusebenza kweyunithi yonke yamandla.Nakuphi na ukungasebenzi kunye nokugqoka amakhonkco kubonakaliswa ngokulahleka kwamandla enjini kunye nokuwohloka ngokubanzi ekusebenzeni kwayo, ngoko ke ezi nxalenye kufuneka zitshintshwe.Kodwa ngaphambi kokuthenga okanye uku-odola amakhonkco amatsha, kufuneka uqonde iintlobo ezikhoyo zala malungu, ukuyila kwawo kunye neempawu zomsebenzi.

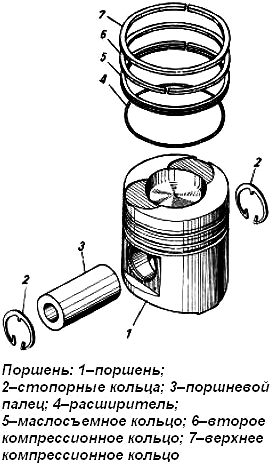

Amakhonkco episton kunye nepiston

Iindidi, uyilo kunye nomgaqo wokusebenza kwamakhonkco episton

Iintlobo ezimbini zamakhonkco zifakwe kwipiston enye:

● Ukucinezela (phezulu);

● I-oil scrapers (ephantsi).

Zonke iindandatho zibekwe kwiigrooves ezinqamlezayo (iigrooves) zeprofayili yoxande, eyenziwe kufutshane nentloko yepiston.Iindandatho zeentlobo ezahlukeneyo ziyahluka ngokuyila kunye nenjongo.

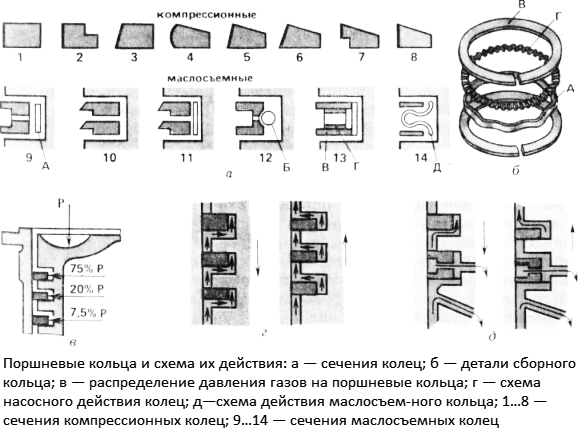

Amakhonkco oxinzelelo abonelela ngokutywinwa kwegumbi lokutsha, amakhonkco amabini, amabini okanye amathathu anokufakwa kwipiston enye (enye kwiinjini zokutsha zangaphakathi ezinezithuthuthu, ezimbini kwiinjini zanamhlanje ezine-stroke, ezintathu kwezinye iinjini zedizili). zibekwe kwindawo ephezulu yepiston.Ngokwesakhiwo, izindandatho zokuxinzelela zilula kakhulu: le yintsimbi yentsimbi, ukunqunyulwa kwayo okwenziwe ngendlela elula (echanekileyo, e-oblique) okanye i-lock eyinkimbinkimbi, kwezinye iindandatho kwisitshixo kukho ikhefu lokumisa.I-lock ine-gap encinci (i-micrometers ezininzi), esebenza ukuhlawulela ukwanda kwe-thermal yecandelo ngexesha lokusebenza kwe-injini.

Amakhonkco ayenziwe ngentsimbi okanye amabakala akhethekileyo entsimbi, indawo yawo yangaphandle (yokusebenza) ingaba neprofayili eyahlukileyo:

● I-Flat elula - kule meko, iringi ine-cross-section ye-rectangular okanye icandelo ngendlela ye-quadrilateral engaqhelekanga;

● I-Radius (i-barrel-shaped) - indawo yangaphandle yendandatho yi-arc yesangqa se-radius enkulu;

● Nge-chamfer - i-chamfer yokuphakama okuncinci yenziwe kwindawo yangaphandle;

● "Umzuzu" amakhonkco - indawo yangaphandle inethambeka ukuya phezulu, i-angle of inclination ingamashumi amashumi emizuzu ye-arc, ngenxa yokuba iindandatho zinegama labo.

Iprofayili ye-flat inezindandatho eziphezulu zokuxinzelela, eziphoqelelwe ukuba zisebenze kumaqondo aphezulu kunye noxinzelelo kwiimeko zokungabikho ngokwaneleyo kwe-lubrication.Ukunciphisa ukugqoka, indawo yokusebenza yecandelo i-chrome-plated, i-phosphated, i-tin efakwe okanye iphathwe ngenye indlela.Indandatho enjalo isondele ngokupheleleyo kwisibuko se-cylinder ngexesha lokusebenza, ukubonelela ukutywinwa kunye nokususwa kobushushu kwipiston.

Izangqa ezisezantsi zihlala zineprofayili enzima ngakumbi.Iringi zomphanda zinokumelana okuncinci kokukhuhlane ngelixa zigcina iqondo elaneleyo lokutywinwa."Umzuzu" amakhonkco, ngenxa yokuthambekela kwendawo esebenzayo, ukunciphisa amandla okukhuhlana: xa ipiston ihla (kwi-stroke esebenzayo), iringi iyatyibilika ecaleni kwesipili se-cylinder esinomgca otsolo, kwaye xa uhambela phezulu, iringi ikhutshiwe kwisibuko se-cylinder ngenxa yesiphumo se-oyile wedge.

Iindandatho ze-oil scraper ziqinisekisa ukuhanjiswa okuchanekileyo kwefilimu yeoli phezu kwendawo yesilinda kunye nokuthintela ioli ekungeneni kwigumbi lokutshisa (yisuse kwisibuko se-cylinder).Indandatho enye kuphela isetyenziswe kwipiston enye, ezi nxalenye azikho kwiipiston zeenjini ezimbini ze-stroke (ekubeni ioli yongezwa ngokuthe ngqo kwipetroli).Ngokuqhelekileyo, iindandatho ze-oil scraper zinedizayini edibeneyo, ebandakanya amakhonkco ngokwawo kunye nezandisi.

Amakhonkco ePiston kunye nesicwangciso sabo sokusebenza

Izangqa ze-oyile zokukrazula zezi:

● Isiqwenga esinye - iringi emise u-U ejonge kwisiseko kwipiston.Kwisiseko kukho uluhlu lwemingxuma ejikelezileyo okanye emide apho i-oil drains yenziwa khona;

● I-Composite - iindandatho ezimbini ezibhityileyo (eziqhekezayo) zisetyenzisiweyo, phakathi kwayo kukho i-spacer element.

Izinto ze-Spacer zezi:

● I-Radial - ukubonelela ngoxinzelelo lwamakhonkco eludongeni lwesilinda;

● I-Axial - isetyenziswe kuphela ngokubambisana neendandatho ezidibeneyo, zibonelela ngokuhlanjululwa kwamakhonkco;

● I-Tangential - i-spacer elements edibeneyo, inika ukwandiswa kwangaxeshanye kwamakhonkco kunye noxinzelelo lwawo ngokubhekiselele eludongeni lwe-cylinder.

Izinto ze-spacer ziyi-plate (i-flat) okanye i-coiled springs efakwe phakathi okanye phantsi kwamakhonkco, kuphela umthombo omnye okanye ezimbini zeentlobo ezahlukeneyo zingasetyenziswa kwindandatho ye-oyile ye-scraper.

I-oil scraper ring icinezelwe eludongeni lwe-cylinder kwaye, ngenxa yoyilo lwayo, iqinisekisa ukukhutshwa kwefilimu yeoli engaphezulu.I-oyile eqokelelweyo ingena emngxunyeni kwimingxunya ekwiringi, ukusuka apho ikhuphela kwi crankcase ye-injini ngemingxuma ekudonga lwepiston.Ngelo xesha, inxalenye yeoli ihlala ikwimo yefilimu yeoli encinci eludongeni lwe-cylinder, okunciphisa ukungqubuzana kuyo yonke i-CPG.

Indlela yokukhetha kunye nokutshintsha amakhonkco episton

Ngexesha lokusebenza kwe-injini, amakhonkco episton aphantsi kwemithwalo ebalulekileyo yoomatshini kunye ne-thermal, ekhokelela ekunxibeni kwabo ngokuthe ngcembe kunye nokulahleka kokusebenza.Njengoko iindandatho ziphela, ziyayeka ukwenza imisebenzi yazo, ekhokelela ekunciphiseni ukunyanzeliswa, ukuphuma kweegesi kwi-crankcase kunye neoli kwigumbi lokutsha.Kwakhona ingxaki enzulu kukuba "ukupheka" kwamakhonkco (i-jamming ngenxa yokuqokelela idiphozithi yekhabhoni kwi-grooves yepiston).Ngenxa yoko, i-injini ilahlekelwa amandla kunye nokuphendula kwe-throttle, i-exhaust ifumana i-gray grey okanye i-tint emnyama, kunye nokusetyenziswa kwepetroli kunye neoli.Xa le miqondiso ibonakala, kuyimfuneko ukuxilonga injini - khangela ukunyanzeliswa, uhlole amakhandlela kunye nezinye iindawo.Ukuba ukunyanzeliswa kuphantsi kakhulu, amakhandlela atshizwa ngeoli kwaye kukho iingxaki ngokusebenza kweyunithi yamandla, ke amakhonkco episton kufuneka atshintshwe.

Ukutshintshwa, kufuneka ukhethe amakhonkco kuphela kwezo ntlobo kunye namanani ekhathalogu abonelelwe kule injini.Kufuneka kukhunjulwe ukuba emva kokwenza ukuguqulwa okukhulu kwe-injini kunye neesilinda ezithandekayo, kuyimfuneko ukusebenzisa amakhonkco obungakanani bokulungisa afanelekileyo kwiipiston ezintsha.

Ukutshintshwa kwamakhonkco kufuneka kuqhutywe ngokuhambelana nemiyalelo yokulungiswa kweyunithi yamandla.Ngokubanzi, lo msebenzi ufuna ukuchithwa kwe-injini kunye nokunciphisa iipiston.Amakhonkco amadala asusiwe kwaye i-grooves ihlanjululwe ngokucokisekileyo.Makufakwe amakhonkco amatsha ngokungqinelana nemiyalelo yamanqaku "Top" okanye "Up" kuzo.Xa ufaka amakhonkco, izikhewu phakathi kwendawo yecala yecala kunye nodonga lwe-groove kwi-piston, kunye nokutshixa kwendandatho efakwe kwi-cylinder, ihlolwe.Lonke ucocilelo kufuneka lube phakathi kwemida emiselweyo yemoto.Amakhonkco abekwe kwi-piston ukwenzela ukuba izitshixo zabo zingalali kumgca ofanayo kwaye zingaweli kwi-axis yemingxuma yeminwe - yile ndlela i-labyrinth eyenziwe ngayo evimbela ukuphumelela kweegesi ezivela kwigumbi lokutsha.

Xa ufaka ipiston ngamakhonkco amatsha kwi-cylinder, kufuneka kusetyenziswe i-mandrel ekhethekileyo ecinezela amakhonkco ngokuchasene nepiston.Emva kokutshintsha amakhonkco e-piston, kuyacetyiswa ukuba usebenze kwi-injini - musa ukugqithisa isantya kwi-800-1000 km yokuqala kwaye ulayishe injini ngesiqingatha samandla, ekupheleni kokuphazamiseka, kufuneka utshintshe ioli ye-injini. .

Ngokukhetha okufanelekileyo kunye nokutshintshwa kwamakhonkco episton, injini iya kuphinda ifumane amandla ayo angaphambili kwaye iya kusebenza ngokuzithemba kuzo zonke iindlela.

Ixesha lokuposa: Jul-13-2023