Inkqubo ye-pneumatic yeemoto kunye neetrektara isebenza ngokuqhelekileyo kuluhlu oluthile loxinzelelo, xa uxinzelelo lutshintsha, ukungaphumeleli kwayo kunye nokuphazamiseka kunokwenzeka.Ukuqina koxinzelelo kwinkqubo inikezelwa ngumlawuli - funda malunga nale yunithi, iintlobo zayo, isakhiwo, ukusebenza, kunye nokulungiswa kunye nohlengahlengiso kwinqaku.

Yintoni umlawuli woxinzelelo?

Umlawuli woxinzelelo yinxalenye yenkqubo ye-pneumatic yezithuthi kunye nezixhobo ezahlukeneyo;Isixhobo esiqinisekisa ukuqina koxinzelelo lomoya kwinkqubo, kwaye yenza imisebenzi emininzi yokukhusela kunye nokukhusela.

Le yunithi isombulula le misebenzi ilandelayo:

• Ukugcina uxinzelelo lomoya kwinkqubo kwibala elimiselweyo (650-800 kPa, kuxhomekeke kuhlobo lwezixhobo);

• Ukukhuselwa kwenkqubo ye-pneumatic ekunyukeni koxinzelelo ngaphezu komda omiselweyo (ngaphezu kwe-1000-1350 kPa, kuxhomekeke kuhlobo lwesixhobo);

• Ukuthintelwa kunye nokukhuselwa kwenkqubo ekungcolisekeni nasekudlekeni ngenxa yokukhutshwa kwecondensate ngamaxesha athile emoyeni.

Umsebenzi oyintloko womlawuli kukugcina uxinzelelo lomoya kwinkqubo ngaphakathi koluhlu olusebenzayo olusekiweyo, kungakhathaliseki ukuba imithwalo yangoku, inani labathengi abadibeneyo, iimeko zemozulu, njl. Ekugqibeleni, ngexesha lokunciphisa uxinzelelo oluqhelekileyo ngokusebenzisa umlawuli, i-condensate eqokelelwe kumacandelo enkqubo (ingakumbi kwi-condensing receiver ekhethekileyo) isuswe emoyeni, ebakhusela ekungcoleni, ekukhenkceni nasekungcoliseni.

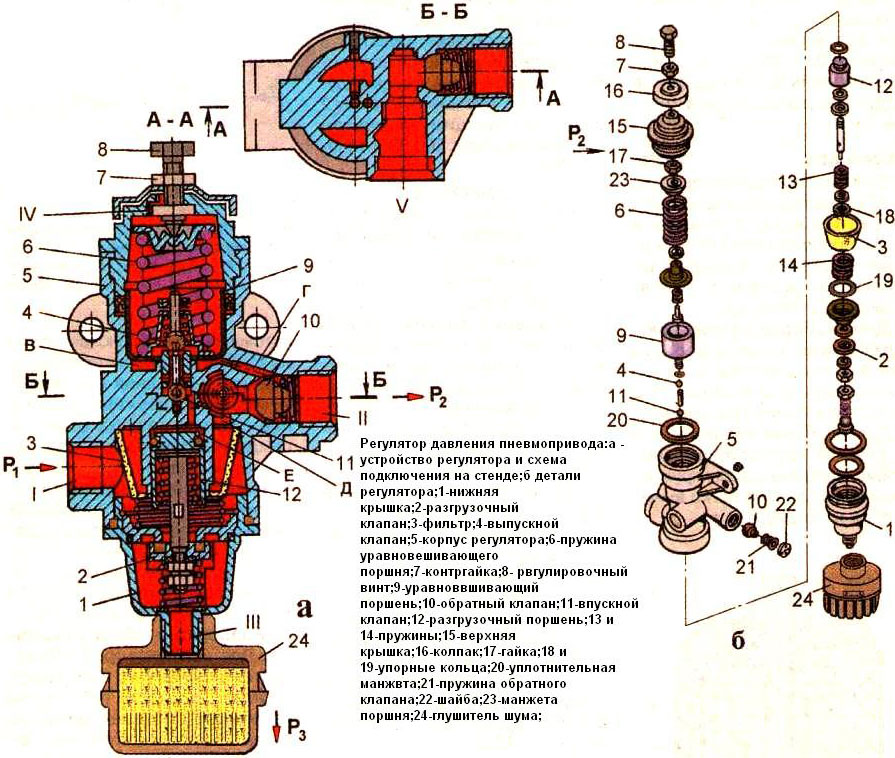

Isixhobo kunye nomgaqo wokusebenza komlawuli woxinzelelo

Kukho iintlobo ezininzi kunye neemodeli zolawulo loxinzelelo kwimarike namhlanje, kodwa zonke ziwela kumaqela amabini amakhulu:

• Abalawuli abasemgangathweni;

• Abalawuli badityaniswe ne-adsorber.

Izixhobo zodidi lokuqala zilawula uxinzelelo kwinkqubo kwaye zenze imisebenzi yokukhusela, ngelixa i-air dehumidification iqhutyelwa yicandelo elihlukeneyo - i-saparator yomswakama kunye neoli (okanye i-oyile eyahlukileyo kunye nesomisi somoya).Izixhobo zodidi lwesibini zixhotyiswe nge-cartridge ye-adsorber, enika i-air dehumidification eyongezelelweyo, inika ukhuseleko olungcono kwi-pneumatic system.

Bonke abalawuli banesixhobo esifanayo ngokusisiseko, ngamnye kubo ubonelela ngezinto ezininzi ezisisiseko:

Uyilo lokulawula uxinzelelo

• Iivalvu zokungena kunye nokukhupha kwisiqu esinye;

• I-valve engabuyiyo (ebekwe kwicala lombhobho wokuphuma, ikhusela ukuhla koxinzelelo kwinkqubo xa i-compressor icinyiwe);

• Ivalve yokukhupha (ebekwe kwicala lendawo esezantsi ye-atmospheric, ibonelela ngokuphuma komoya emoyeni);

• Ipiston yokulinganisa edityaniswe kwiivalvu zokungena kunye nokukhupha (ibonelela ngokuvula / ukuvala iivalvu zokungena kunye nokukhupha, iqondisa ngokutsha ukuhamba komoya ngaphakathi kwesilawuli).

Zonke iinxalenye kunye namacandelo eyunithi abekwe kwimeko yesinyithi kunye nenkqubo yamajelo kunye nemigodi.Umlawuli uneendawo ezine zokuphuma (umbhobho) wokudibanisa kwinkqubo ye-pneumatic yemoto: i-inlet - umoya oxinzelelweyo ovela kwi-compressor ungena kuyo, imveliso - ngayo umoya ovela kumlawuli ungena kwinkqubo, i-atmospheric-compressed air kunye ne-condensate ikhutshwe kuyo. iatmosfera ngayo, kwaye ikhethekileyo kumatayara avuzayo.I-atmospheric outlet inokuxhotyiswa nge-muffler-isixhobo sokunciphisa ubunzulu bengxolo evela kuxinzelelo loxinzelelo.I-outlet ye-inflation yesondo yenziwe ngendlela yokudibanisa i-hose, ivalwe nge-cap yokukhusela.Kwakhona, umlawuli unikeza enye imveliso ye-atmospheric ye-cross-section encinci, kuyimfuneko ekusebenzeni okuqhelekileyo kwepiston yokukhupha, iipayipi azixhunyiwe kule terminal.

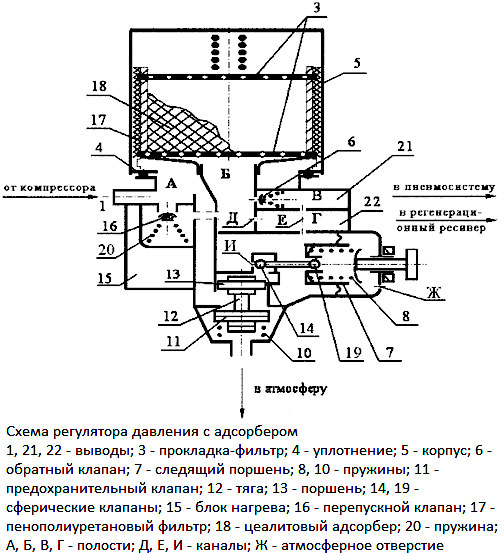

Kwizilawuli ezine-adsorber, isitya esigcwele izinto ze-hygroscopic siqhotyoshelwe kwindlu, sithatha umswakama ovela emoyeni ovela kwi-compressor.Ngokuqhelekileyo, i-adsorber yenziwe ngendlela ye-cartridge eqhelekileyo kunye nentaba ene-threaded, enokutshintshwa xa kuyimfuneko.

Ukusebenza komlawuli woxinzelelo akukho nzima kakhulu.Xa injini iqala, umoya ocinezelweyo ovela kwicompressor ungena kwi-terminal ehambelanayo yomlawuli.Ngethuba nje uxinzelelo lukuluhlu lokusebenza okanye ngaphantsi, iivalve zikwimeko apho umoya uhamba ngokukhululekileyo ngokusebenzisa umlawuli kwisistim, uzalise abamkeli kwaye uqinisekisa ukusebenza kwabathengi (i-exhaust kunye ne-check valves zivulekile, iivalve zokungena kunye nokukhupha zivaliwe).Xa uxinzelelo lusondela kumda ophezulu woluhlu lokusebenza (750-800 kPa), i-valve yokukhulula kunye ne-inlet ivulekile, kwaye i-valve yokujonga kunye ne-exhaust valve ivala, ngenxa yoko, indlela yomoya iyatshintsha - ingena kwi-outlet ye-atmospheric kwaye ikhutshwe. .Ngaloo ndlela, i-compressor iqala ukungasebenzi, ukunyuka kwengcinezelo kwinkqubo yokuyeka.Kodwa ngokukhawuleza ukuba uxinzelelo kwinkqubo yehla ukuya kumda ophantsi woluhlu lokusebenza (620-650 kPa), iivalve zihamba kwindawo apho umoya ovela kwi-compressor uqala ukugeleza ubuyele kwinkqubo.

Kwimeko apho umlawuli ucima i-compressor xa uxinzelelo lufikelela kwi-750-800 kPa, ngoko kwixesha elizayo indlela yokukhusela iya kusebenza, indima edlalwa yi-valve efanayo yokukhupha.Kwaye ukuba uxinzelelo lufikelela kwi-1000-1350 kPa, i-valve yokukhulula ivula, kodwa amacandelo asele eyunithi ayitshintshi indawo yabo - ngenxa yoko, inkqubo ixhunyiwe kwi-atmosphere, ukukhutshwa koxinzelelo oluphuthumayo kwenzeka.Xa uxinzelelo lwehla, i-valve yokukhupha ivala kwaye inkqubo iyaqhubeka isebenza ngokuqhelekileyo.

Uxinzelelo apho i-compressor inqanyuliwe kwi-pneumatic system imiselwe ngamandla entwasahlobo yepiston yokulinganisa.Ingatshintshwa ngokusebenzisa isikrufu sokulungisa siphumle kwipleyiti yasentwasahlobo.I-screw igxininiswe yi-locknut, ethintela umatshini ekubeni ufile ngenxa ye-vibrations, izothuso, i-jolts, njl.

Abalawuli abane-adsorber basebenza ngokufanayo, kodwa banikezela ngemisebenzi emibini eyongezelelweyo.Okokuqala, xa uxinzelelo lukhutshwa, umoya awukhululwa nje emoyeni - udlula kwi-adsorber kwelinye icala, ususa ukufuma okuqokelelweyo kuyo.Kwaye, okwesibini, xa i-adsorber ivaliwe (umoya ovela kwi-compressor uyahluzwa, kodwa kukho rhoqo umlinganiselo othile wokungcola kuyo, efakwe kwiincinci ze-adsorbent), i-valve yokudlula iyashukunyiswa, kwaye umoya uvela ukukhupha umgca ungena ngqo kwinkqubo.Kule meko, umoya awuhlanjululwanga, kwaye i-adsorber kufuneka itshintshwe.

Umlawuli woxinzelelo lwalo naluphi na uhlobo lufakwe kumgca wokukhutshwa kwenkqubo ye-pneumatic ngokukhawuleza emva kwe-compressor kunye ne-oyile kunye ne-mobile separator (ukuba ibonelelwe kwinkqubo).Umoya ovela kumlawuli, ngokuxhomekeke kwisekethe yenkqubo ye-pneumatic, unokubonelelwa kwi-fuse yefrize kwaye emva koko kwivalve yokhuseleko, okanye kuqala kwi-condensing receiver kwaye emva koko kwivalve yokhuseleko.Ngale ndlela, umlawuli ubeka esweni uxinzelelo kwinkqubo yonke kwaye uyayikhusela ekugqithiseni.

Umzobo womlawuli woxinzelelo kunye ne-adsorber

Imiba yokukhetha kunye nokulungiswa kwabalawuli boxinzelelo

Ngethuba lokusebenza, umlawuli woxinzelelo ubonakaliswe kungcoliseko kunye nemithwalo enzima, ehamba ngokuthe ngcembe ekhokelela ekudakaleni kokusebenza kwayo kunye nokuphuka.Ukongezwa kobomi benkonzo yomlawuli kufezekiswa ngokuhlolwa nokucoca ngexesha lokugcinwa kwesithuthi.Ngokukodwa, kuyimfuneko ukucoca i-strainers eyakhelwe kubalawuli kwaye ukhangele yonke iyunithi yokuvuza.Kubalawuli abane-adsorber, kuyimfuneko kwakhona ukutshintsha i-cartridge kunye ne-adsorbent.

Kwimeko yokungasebenzi kakuhle komlawuli - ukuvuza, ukusebenza okungalunganga (ukungaphumeleli ukucima i-compressor, ukulibaziseka kokukhutshwa komoya, njl.) - iyunithi kufuneka ilungiswe okanye ithathelwe indawo kwindibano.Kwimeko yokutshintshwa, kufuneka ukhethe umlawuli wohlobo olufanayo kunye nemodeli efakwe kwimoto (okanye i-analogue yayo ehambelana neempawu zenkqubo ye-pneumatic).Emva kofakelo, isixhobo esitsha kufuneka sihlengahlengiswe ngokuhambelana neengcebiso zomenzi wesithuthi.Ngokukhetha okufanelekileyo kunye nokutshintshwa komlawuli, inkqubo ye-pneumatic iya kusebenza ngokuthembekileyo kwiimeko ezahlukeneyo.

Ixesha lokuposa: Aug-05-2023