Injini nganye yokutsha yangaphakathi iqulethe intloko ye-cylinder (intloko ye-cylinder) - inxalenye ebalulekileyo yokuba, kunye nentloko yepiston, yenza igumbi lokutsha, kwaye idlala indima ebalulekileyo ekusebenzeni kweenkqubo zomntu ngamnye weyunithi yamandla.Funda konke malunga neentloko ze-cylinder, iintlobo zazo, ukuyila, ukusetyenziswa, ukugcinwa kunye nokulungiswa kweli nqaku.

Yintoni intloko yesilinda?

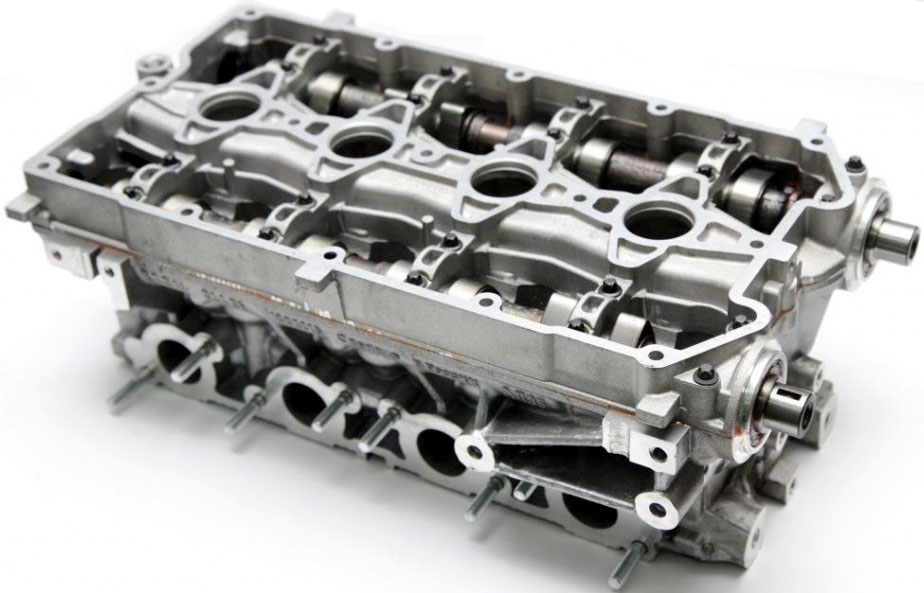

Intloko ye-cylinder (intloko ye-cylinder) yiyunithi ye-injini yokutsha yangaphakathi efakwe phezulu kwibhloko yesilinda.

Intloko ye-cylinder yenye yezona nxalenye eziphambili ze-injini yokutsha yangaphakathi, iqinisekisa ukusebenza kwayo kwaye imisela iimpawu zayo eziphambili zokusebenza.Kodwa intloko iphathiswe inani lemisebenzi:

• Ukuqulunqwa kwamagumbi okutsha - kwindawo engezantsi yentloko, ebekwe ngokuthe ngqo phezu kwe-cylinder, igumbi lokutsha lenziwa (inxalenye okanye ngokupheleleyo), ivolumu yayo epheleleyo yenziwa xa i-piston ye-TDC ifikeleleke;

• Ukunikezelwa komoya okanye umxube we-fuel-air kwigumbi lokutsha - iziteshi ezihambelanayo (i-intake) zenziwe kwintloko ye-cylinder;

• Ukususwa kweegesi zokukhutshwa kumagumbi okutsha - iziteshi ezihambelanayo (ukukhupha) zenziwe kwintloko ye-cylinder;

• Ukupholisa kweyunithi yamandla - kwintloko ye-cylinder kukho iziteshi zebhatyi yamanzi apho i-coolant ijikeleza khona;

• Ukuqinisekisa ukusebenza kwendlela yokuhambisa irhasi (ixesha) - iivalvu zibekwe entloko (kunye nazo zonke iindawo eziyeleleneyo - iibhushi, izihlalo) ezivula zivale imigudu yokungena kunye neyokukhupha ngokuhambelana neestroyikhi zenjini.Kwakhona, ixesha lonke linokuthi libekwe entloko - i-camshaft (i-shafts) kunye neebheringi zabo kunye neegesi, i-valve drive, imithombo yevalve kunye nezinye iindawo ezinxulumene nazo;

• Ukuthanjiswa kwamalungu exesha - imijelo kunye nezikhongozeli zenziwa entloko, apho ioli ihamba khona ukuya kwiindawo zokuxubha;

• Ukuqinisekisa ukusebenza kwenkqubo yokutofa kwepetroli (kwiinjini zedizili kunye nenaliti) kunye / okanye inkqubo yokutshisa (kwiinjini zepetroli) - ii-injini zepetroli kunye / okanye iiplagi zentlantsi ezineendawo ezinxulumeneyo (kunye neeplagi zokuvutha kwedizili) zixhonywe phezu intloko

• Ukusebenza njengelungu lomzimba lokuxhoma amacandelo ahlukeneyo - i-intake kunye ne-exhaust manifolds, izinzwa, imibhobho, izibiyeli, iirola, izigqubuthelo kunye nabanye.

Ngenxa yoluhlu olubanzi lwemisebenzi, iimfuno ezingqongqo zibekwe kwintloko ye-cylinder, kwaye uyilo lwayo lunokuba nzima kakhulu.Kwakhona namhlanje kukho iintlobo ezininzi zeentloko apho umsebenzi ochaziweyo uphunyezwa ngendlela enye okanye enye.

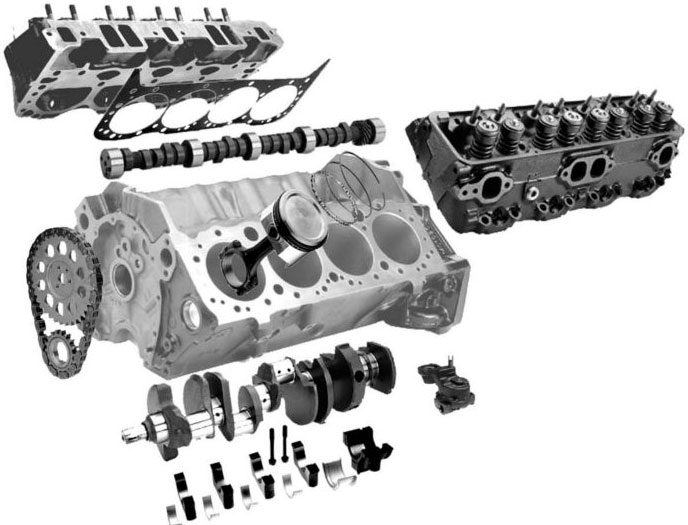

Iintlobo zeentloko ze-cylinder

Iintloko ze-cylinder zihluke ngokuyila, uhlobo kunye nendawo yegumbi lokutsha, ubukho kunye nohlobo lwexesha, kunye nenjongo kunye nezinye iimpawu.

iintloko zesilinda zinokuba noyilo olunye kwezine:

• Intloko eqhelekileyo yazo zonke iisilinda kwiinjini ze-in-line;

• Iintloko eziqhelekileyo zoluhlu lweesilinda kwii-injini ezinobu-V;

• Iintloko ezihlukeneyo zeesilinda ezininzi zeenjini ze-multi-cylinder in-line;

• Iintloko ze-cylinder nganye kwi-single-, ezimbini kunye ne-multi-cylinder inline, i-V-shaped kunye nezinye iinjini.

Iindidi eziphambili zamagumbi okutsha eenjini zokutsha zangaphakathi

Kwii-injini ze-2-6-cylinder eziqhelekileyo, iintloko eziqhelekileyo zihlala zisetyenziselwa ukugubungela zonke iisilinda.Kwii-injini ze-V, zombini iintloko ze-cylinder eziqhelekileyo kumqolo omnye weesilinda kunye neentloko zomntu ngamnye kwi-cylinder nganye zisetyenziswa (umzekelo, ii-injini ezisibhozo ze-KAMAZ 740 zisebenzisa iintloko ezihlukeneyo kwi-cylinder nganye).Iintloko ze-cylinder ezahlukeneyo zeenjini ze-in-line zisetyenziswa kakhulu ngaphantsi rhoqo, ngokuqhelekileyo intloko enye igubungela iisilinda ezi-2 okanye ezi-3 (umzekelo, kwii-injini zedizili ezi-6-cylinder MMZ D-260 iintloko ezimbini zifakwe - enye yeesilinda ezi-3).Iintloko ze-cylinder zomntu ngamnye zisetyenziswa kwiinjini zedizili ezinamandla (umzekelo, kwiinjini zedizili ze-Altai A-01), kunye nakwiiyunithi zamandla zoyilo olukhethekileyo (ibhokisi lebhokisi elinesilinda, inkwenkwezi, njl.njl.).Kwaye ngokwemvelo, iintloko zodwa zingasetyenziselwa kwiinjini ze-cylinder enye, ezenza kwakhona imisebenzi ye-radiator epholileyo emoyeni.

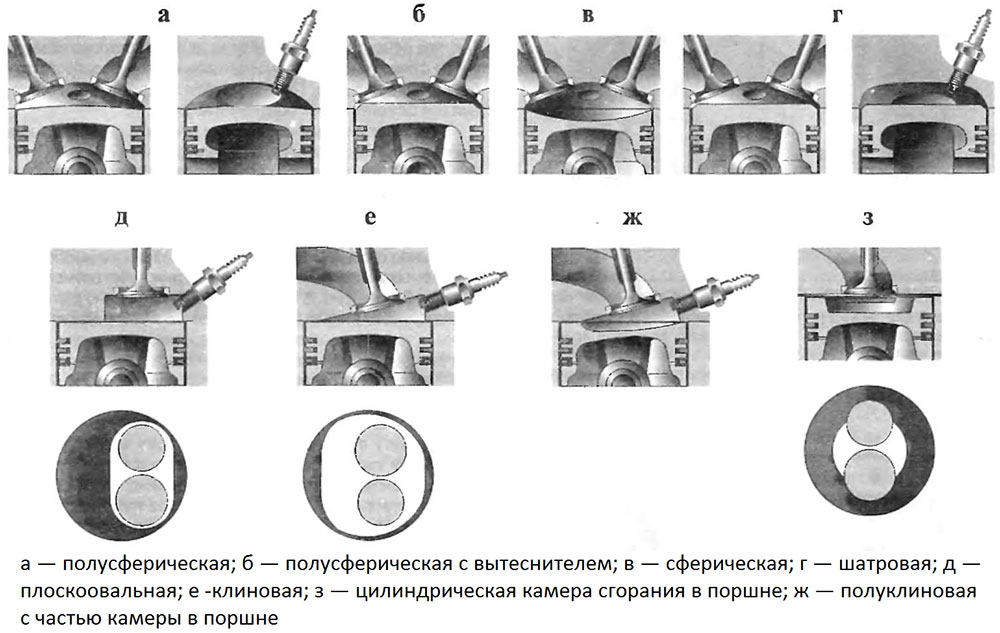

Ngokwendawo yegumbi lokutsha, kukho iintlobo ezintathu zeentloko:

• Ngegumbi lokutsha kwintloko ye-cylinder - kule meko, i-piston ene-flat bottom isetyenzisiweyo, okanye i-displacer;

• Ngegumbi lokutsha kwintloko ye-cylinder kunye ne-piston - kule meko, inxalenye yegumbi lokutsha lenziwa kwintloko yepiston;

• Ngegumbi lokutsha kwipiston - kule meko, indawo engaphantsi yentloko ye-cylinder isicaba (kodwa kunokubakho iindawo zokubeka iivalve kwindawo ethambekeleyo).

Ngexesha elifanayo, amagumbi okutsha anokuba neemilo ezahlukeneyo kunye nokucwangciswa: i-spherical and hemispherical, i-hiped, i-wedge kunye ne-semi-wedge, i-flat-oval, i-cylindrical, i-complex (edibeneyo).

Ngokobukho bamacandelo exesha, intloko yeyunithi zezi:

• Ngaphandle kwexesha - iintloko ze-multi-cylinder low-valve kunye ne-single-cylinder ezine-stroke iinjini ezingena-valve;

• Ngeevalve, iingalo zerocker kunye namacandelo anxulumeneyo - iintloko ze-injini ezinecamshaft esezantsi, zonke iindawo zibekwe phezulu kwentloko yesilinda;

• Ngexesha elipheleleyo - icamshaft, ivalve drive kunye neevalvu ezinamalungu ahambelanayo, onke amalungu abekwe kwindawo ephezulu yentloko.

Ekugqibeleni, iintloko zinokwahlulwa ngokwenjongo yazo kwiintlobo ezininzi - kwidizili, i-petroli kunye neeyunithi zamandla egesi, kwiinjini eziphantsi kwesantya kunye nokunyanzeliswa, kwiinjini zokutsha zangaphakathi ezipholileyo kunye nomoya opholileyo, njl. Kuzo zonke ezi meko. , iintloko ze-cylinder zineempawu ezithile zokuyila - imilinganiselo, ubukho bokupholisa okanye i-fin channels, imilo yamagumbi okutsha, njl.

uyilo lwentloko yesilinda

Icandelo lentloko yesilinda

Ngokwesakhiwo, intloko yesilinda yinxalenye eqinileyo eyenziwe ngesixhobo esine-conductivity ephezulu ye-thermal - namhlanje ihlala i-alloys ye-aluminium, intsimbi emhlophe kunye nezinye i-alloys nazo zisetyenziswa.Zonke iinxalenye zeenkqubo ezikuyo zenziwe entloko - imigudu yokungena kunye nokukhupha, imingxuma yevalve (i-valve guide bushings icinezelwe kuwo), amagumbi okutsha, izihlalo zevalve (zingenziwa ngee-alloys ezinzima), iindawo ezixhasayo zokuxhoma. iindawo zokubeka ixesha, amaqula kunye nemingxuma exhonyiweyo yokufaka amakhandlela kunye / okanye imilomo, imijelo yenkqubo yokupholisa, imijelo yenkqubo yokuthambisa, ukuba intloko yenzelwe injini ene-camshaft engaphezulu, ke ibhedi yenziwa kwindawo yayo ephezulu yokubeka i-shaft. (ngeentsimbi).

Kwiindawo ezisecaleni zentloko ye-cylinder, iindawo zokuzalisa zenziwe ukunyuswa kwe-intake kunye ne-exhaust manifolds.Ukufakwa kwezi nxalenye kuqhutyelwa ngokutywinwa kwee-gaskets ezingabandakanyi ukuvuza komoya kunye nokukhupha ukuvuza.Kwiinjini zanamhlanje, ukufakwa kwezi kunye namanye amacandelo entloko kuqhutyelwa ngeendlela ze-studs kunye namantongomane.

Kumgangatho ophantsi wentloko ye-cylinder, indawo yokuzalisa yenzelwe ukukhwela kwibhloko.Ukuqinisekisa ukuqina kwamagumbi okutsha kunye nemijelo yenkqubo yokupholisa, i-gasket ibekwe phakathi kwentloko ye-cylinder kunye neziko loshishino.Ukutywinwa kunokwenziwa ngee-gaskets eziqhelekileyo ezenziwe nge-paronite, izinto ezisekelwe kwi-rubber, njl., Kodwa kwiminyaka yamuva nje, iipakethi zetsimbi ezibizwa ngokuba zisetyenziswe ngokugqithiseleyo - i-copper-based composite gaskets ene-synthetic inserts.

Inxalenye ephezulu yentloko ivalwe ngesivalo (intsimbi egxininisiweyo okanye iplastiki) kunye nentamo yokuzalisa ioli kunye ne-stopper.Ukufakwa kwekhava kuqhutyelwa nge-gasket.Isigqubuthelo sikhusela iinxalenye zexesha, iivalvu kunye nemithombo kumdaka kunye nomonakalo, kwaye ikwathintela ukuchitheka kweoyile ngelixa imoto ihamba.

Uyilo lwentloko yesilinda

Ukufakwa kwentloko ye-cylinder kwibhloko kuqhutyelwa ngeendlela ze-studs okanye iibholiti.Izitudi zikhethwa ngakumbi kwiibhloko ze-aluminium, njengoko zibonelela nge-clamp ethembekileyo entloko kwaye zisasaze ngokulinganayo imithwalo emzimbeni webhloko.

Iintloko ze-cylinder zeenjini ezipholileyo zomoya (isithuthuthu, i-scooter kunye nabanye) zinamaphiko kumphezulu ongaphandle - ubukho bamaphiko kwandisa kakhulu indawo yentloko, ukuqinisekisa ukupholisa kwayo okusebenzayo ngokuhamba komoya okuzayo.

Imiba yokugcinwa, ukulungiswa kunye nokutshintshwa kwentloko ye-cylinder

Intloko ye-cylinder kunye namacandelo afakwe kuyo aphantsi kwemithwalo ebalulekileyo, ekhokelela ekugqokeni kwabo okunzulu kunye nokuphuka.Njengomthetho, ukungasebenzi kakuhle kwentloko ngokwayo akuqhelekanga - ezi zizinto ezahlukeneyo zokuguqulwa, iintanda, umonakalo ngenxa yokubola, njl. indawo (ngaphandle kohlengahlengiso).

Ngokuqhelekileyo, ukuphuka kwentloko ye-cylinder kwenzeka kwiinkqubo ezifakwe kuyo - ixesha, ukuthambisa, njl. Ngokuqhelekileyo oku kunxitywa kwezihlalo zevalve kunye ne-bushings, iivalve ngokwazo, iinxalenye zokuqhuba, i-camshaft, njl. Kuzo zonke ezi meko, iindawo ezineziphene zitshintshwa okanye ilungiswe.Nangona kunjalo, kwigaraji, ezinye iintlobo zokulungiswa kunzima ukwenza, umzekelo, ukucofa kunye nokucofa i-valve guide bushings, izihlalo zevalve kunye nomnye umsebenzi kunokwenzeka kuphela ngesixhobo esikhethekileyo.

Ingqwalasela ngokukodwa kufuneka ihlawulwe ekufakweni ngokuchanekileyo kwentloko ye-cylinder.Kubalulekile ukukhumbula ukuba i-cylinder head gasket iyalahlwa, kufuneka itshintshwe ukuba intloko iyachithwa, ukufakwa kwakhona kwale nxalenye akuvumelekanga.Xa ufaka intloko ye-cylinder, umyalelo ochanekileyo wokuqinisa i-fasteners (i-studs okanye i-bolts) kufuneka ibonwe: ngokuqhelekileyo umsebenzi uqala ukusuka phakathi kwentloko kunye nokunyakaza ukuya emaphethelweni.Ngolu kuqina, umthwalo entloko usasazwa ngokulinganayo kwaye ukukhubazeka okungamkelekanga kuthintelwe.

Ngethuba lokusebenza kwemoto, ukugcinwa kwentloko kunye neenkqubo ezikuyo kufuneka zenziwe ngokuhambelana nemiyalelo kunye neengcebiso zomenzi.Ngokulungiswa kwexesha kunye nokulungiswa, intloko yesilinda kunye ne-injini yonke iya kusebenza ngokuthembekileyo nangokufanelekileyo.

Ixesha lokuposa: Aug-21-2023